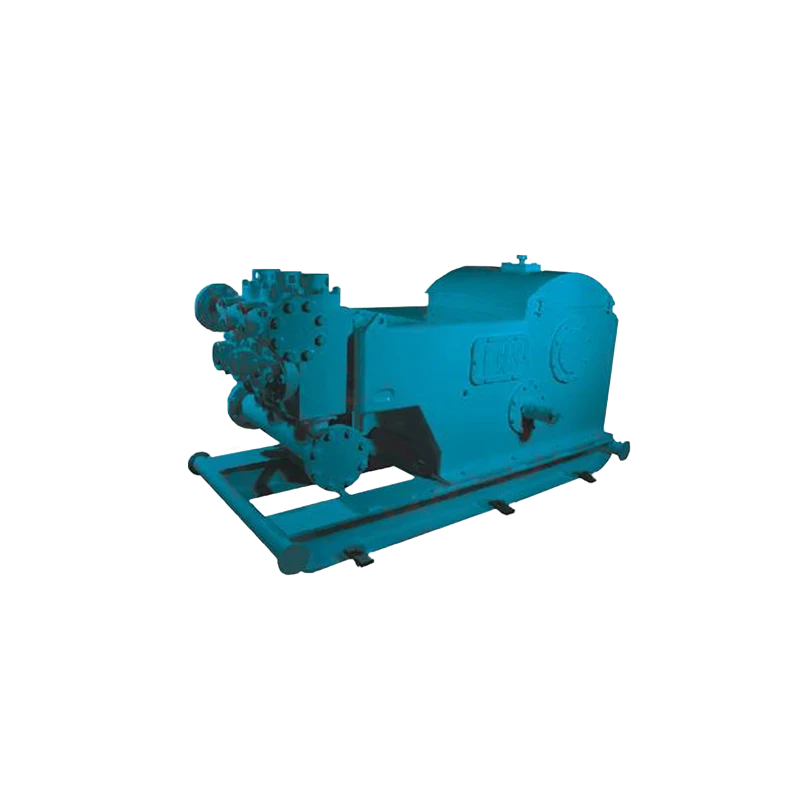

W Series W440 Mud Pump

W-440/446(500HP)pumps can be widely used in all types of operations in an oilfield. The liner sizes range from 6 to 3 1/2, which are suitable to adopt piston structure for well maintenance and shallow drilling. The pumps with liner sizes of 3 1/42 adopts piston structure and such pumps can be used in conditions with high pressure. The pump is compact in structure, and has a small size therefore it is light. The gear pairs are in a integral herringbone structure and the transmission torque is large.

Parameter of W Series W440 Mud Pump

W-440/446(500HP)pumps can be widely used in all types of operations in an oilfield. The liner sizes range from 6 to 3 1/2, which are suitable to adopt piston structure for well maintenance and shallow drilling. The pumps with liner sizes of 3 1/42 adopts piston structure and such pumps can be used in conditions with high pressure. The pump is compact in structure, and has a small size therefore it is light. The gear pairs are in a integral herringbone structure and the transmission torque is large.

Frame The machine frames are welded with steel plates and processed to eliminate stress after welding, therefore. There are reinforced plates at the seats of crankshaft and main bearing so that they have good stiffness and strength.

Crankshaft The crankshaft is in a balanced structure with welded forged parts. It is light and can operate smoothly without vibration. The both sides of the crankshaft are equipped with double aligning spherical roller bearings so as to ensure the stability in operation and to improve its bearing capacity.

Pinion Shaft It is made of forge alloy steel, herringbone gears (integral) is machined on the shaft and it adopts medium hard tooth surface. There is shaft extension at both ends, where bell pulleys or chain wheels may be installed

Crosshead The crosshead is made by one-piece cast with nodular cast iron, so the crosshead has good resistance to abrasion. The structure of top and bottom guidance is adopted for crossheads in order to regulate the concentricity by adding gasket at the bottom guidance. The extension rods are connected to the crossheads by flange bolts with pin holes, so as to ensure the concentricity of the crosshead and the extension rods. The packing adopts double layer sealing structure which realizes good seal performance

Fluid Cylinder The cylinder is made of forge alloy steel and adopts a straight-way structure The hydraulic cylinder has a small size and higher volume efficiency. The cylinder surface is processed by chemical plating in order to increase the resistance to corrosion. The three hydraulic cylinders of a pump are interchangeable

Liner W440/446(500HP)pumps have the same liner O.D. The liners are mounted tightly on the end face of hydraulic cylinder by using squareness capping and bolts. Sealing between the liner and the hydraulic cylinder is realized by rectangular rubber gaskets

lubrication System The pump adopts forced lubrication In the oil tank, there is a gear oil pump, which transmits pressure oil to crossheads guidance as well as the bearings, so as to ealize forced lubrication and cooling.

Spraying System It adopts a power driven spraying system.

| W-440 Pump

Parameters |

Stroke,min-1 | 320 | 270 | 220 | 170 | 120 | 70 | |

| Inputpower(horsepower) | 440 | 380 | 320 | 260 | 200 | 200 | ||

| Cylinder diameter | Pressure | Gallon,run-1 | Gallon,run-1 | |||||

| 4-1/2 | 1710 | 1.239 | 397 | 335 | 273 | 211 | 149 | 87 |

| 4-1/4 | 1917 | 10105 | 354 | 299 | 243 | 188 | 133 | 77 |

| 4 | 2169 | 0.979 | 313 | 264 | 215 | 167 | 118 | 69 |

| 3-3/4 | 2468 | 0.861 | 275 | 232 | 189 | 146 | 103 | 60 |

| 3-1/2 | 2816 | 0.750 | 240 | 202 | 165 | 127 | 90 | 52 |

| 3 | 3327 | 0.551 | 204 | 149 | 121 | 94 | 66 | 39 |

( Mechanical efficiency 90%, coefficient of fullness α=100%, and volumetric efficiency 100% )

Want to Know More Detail About This Drilling Equipment?

相关产品

-

Mud Pump

PAH Series PAH350 Mud Pump

-

Mud Pump

F Series F1600 Mud Pump

-

Mud Pump

F Series F800 Mud Pump

-

Mud Pump

3NB1300 Mud Pump