Weldneck Flange

A weld neck flange for the oil and gas industry is designed according to API 6A and API Spec Q1 standards. This flange features a neck on the side opposite the sealing face, which is beveled for welding to the pipe.

Parameter of Weldneck Flange

A weld neck flange for the oil and gas industry is designed according to API 6A and API Spec Q1 standards. This flange features a neck on the side opposite the sealing face, which is beveled for welding to the pipe.

Weld neck flanges are highly regarded in the oil and gas sector for their robustness and reliability in high-pressure and high-temperature environments. They offer a smooth bore, facilitating easy inspection, cleaning, and pipeline modifications. When welded directly to the pipe, they provide a strong, leak-proof connection.

Technical Parameters:

Weldneck flange size: 1-13/16”, 2 1/16”, 3 1/16”, 4-1/16”, 5 1/8”

Weldneck flange pressure: From 3000PSI to 15000PSI.

Weld neck flanges, recognizable by their beveled hubs, are ideal for high-pressure environments and situations involving repeated bending. They are connected to the piping system by welding the pipe to the flange neck. Stainless steel is often chosen for these flanges due to its excellent weldability, making it the preferred material for manufacturing stainless steel pipes. The design of weld neck flanges reduces stress concentration at the hub’s base and helps transfer stress from the flange to the pipe.

Want to Know More Detail About This Drilling Equipment?

相关产品

-

Well Head

Low-Alloy Steel Choke Valve

-

Drilling Rig

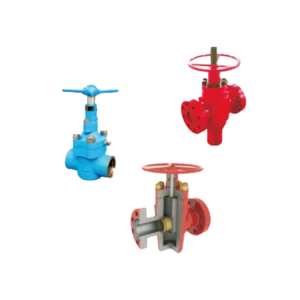

Gate Valve

-

Well Head

Blind Flange

-

Well Head

Tubing Head Spool