Casing Hangers

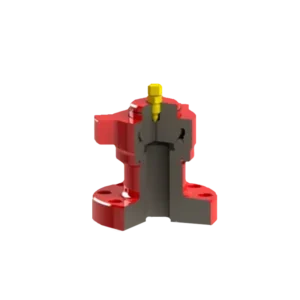

The casing hanger is used for supporting the casing loads and sealing the annular space between the casing and tubing. Casing hanger is used for supporting the casing loads, and sealing the annular space between casing and tubing.

Parameter of Casing Hangers

The casing hanger is used for supporting the casing loads and sealing the annular space between the casing and tubing.

Casing hanger is used for supporting the casing loads, and sealing the annular space between casing and tubing.

Types of Casing Hangers

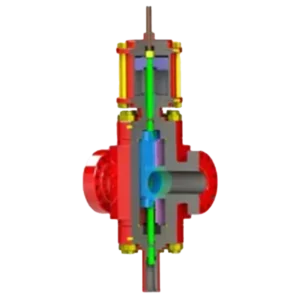

Casing Hanger

The casing hanger consists of a slip. slip bowl, etc. The casing hanger is a slip-type,wrap-around hanger for shallow wells with light casing loads(Max5000psi). The JF Packoff serves as the primary seal and thus can protect the slips from test pressure. The Type H primary seal provides reliable casing suspension and positive annular sealing in all service environments. It is used globally in the wellhead-bowl profiles without lock crews.

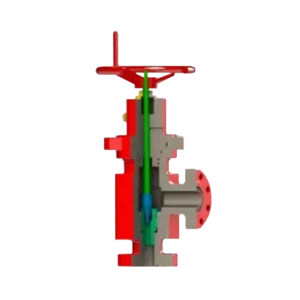

WE-Casing Hanger

The WE-type casing hanger is a wrap-around, slip-type hanger for high load capacity applications which is installed at the casing head or casing spool. The hanger is commonly used over the mud line system.

W-Casing Hanger

The W type casing hanger is a wrap around.slip type hanger for high load capacity applications. It is a kind of weight-set hanger that the weight is supported on a solid shoulder not on seal, thus will not over-compress the seal.

Need for Casing Hangers in the Oil and Gas Industry

Casing hangers play a vital role in the oil and gas industry, especially in the drilling and production of hydrocarbons. They are an essential part of the wellhead and Christmas tree, contributing to the integrity of the well and the safe and efficient extraction of oil and gas resources. In this article, we will explore the uses of casing hangers, the various types available, and the key differences between casing hangers and tubing hangers.

Purpose of Casing Hangers

The main purpose of a casing hanger is to support and seal the casing strings within the wellhead. These casing strings are large diameter pipes that are inserted into the wellbore and secured in place during the drilling process. Casing hangers perform the following key functions:

Support: The casing hanger supports the weight of the casing string, preventing it from collapsing or moving within the wellbore. This ensures the structural integrity of the well.

Seal: The casing hanger creates a seal between the casing and the wellhead, preventing hydrocarbons and other fluids from escaping the well. This is essential for safety and environmental protection.

Isolation: They isolate different sections of the wellbore so that fluids such as cement or drilling mud can be injected and hydrocarbons can be produced from specific reservoir areas.

Casing Hangers vs. Tubing Hangers

Both casing hangers and tubing hangers are components of the wellhead assembly, but they serve different purposes:

Casing hangers: As mentioned above, casing hangers support and seal the casing string, which is a larger diameter pipe that runs deep into the wellbore and is held in place. They are primarily responsible for wellbore integrity and hydrocarbon containment.

Tubing hangers: Tubing hangers, on the other hand, support and seal production tubing, which is a smaller diameter pipe that is used to transport hydrocarbons from the reservoir to the surface. Tubing hangers play a key role in controlling the flow of oil and gas during the production process.

Want to Know More Detail About This Drilling Equipment?

Related products

-

Well Head

Hydraulic Gate Valves

-

Well Head

Low-Alloy Steel Choke Valve

-

Well Head

Weco Flanges

-

Well Head

Tubing Head