Low-Alloy Steel Choke Valve

Choke valve consists of a needle-type adjustable flow valve (JFK), Choke-type Choke valve (JFB), cage-type Choke valve (JFL) and positive Choke valve (JFG) Composition, Design and quality control comply with international standards.

Parameter of Low-Alloy Steel Choke Valve

Choke valve consists of a needle-type adjustable flow valve (JFK), Choke-type Choke valve (JFB), cage-type Choke valve (JFL) and positive Choke valve (JFG) Composition, Design and quality control comply with international standards.

The valve body is made of high-quality low-alloy steel and processed with advanced technology that meets API 6A 20th edition and NACE MR-0175.

The wellhead chokes are used to limit production rates for regulations, protect surface equipment from slugging, avoid sand problems due to high drawdown, and control flow rate to avoid water or gas coning.

Types

Choke valves are supplied in two types: Positive and Adjustable.

Designed as per API6A, API 16C, NACE MR0175.

Structure type: needle, barrel, cage,orifice and wedge;

Working pressure: 3000psi,5000psi, 10000psi, 15000psi

Nominal bore: 2 1/16″,2 9/16″,3 1/16″ 3 1/8”,4 1/16

Positive Choke Valve

Positive chokes allow external adjustment in orifice

size 5/64″ through 48/64″ in 1/64″ increments

Adjustable Choke Valve

Adjustable chokes Indicator sleeve reveals orifice size in 1/64″increments needed for conversion to an equivalent positive choke size

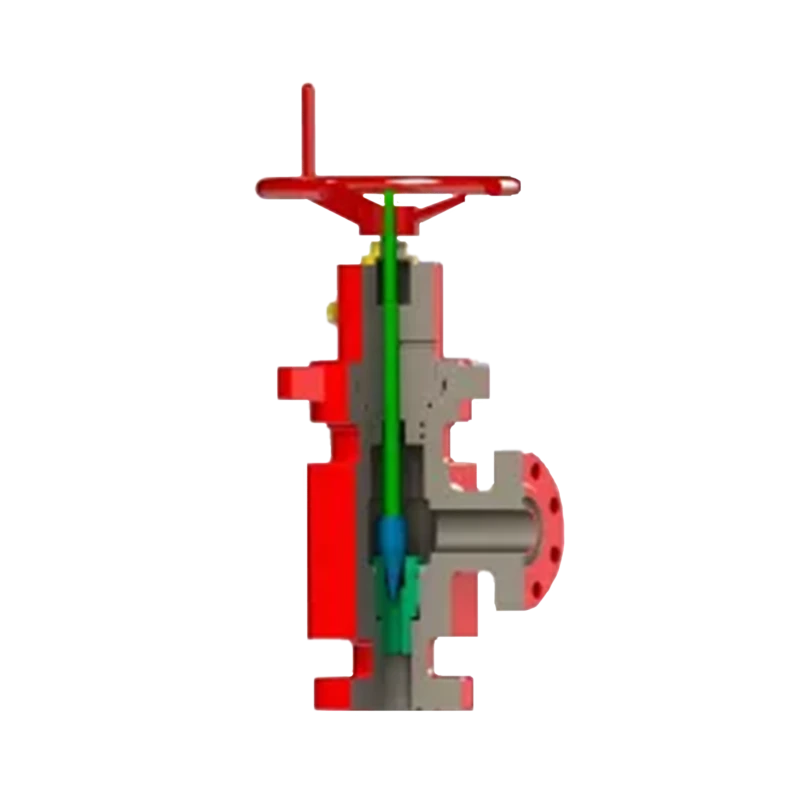

Needle type Choke Valve

Mainly used for wellhead Christmas tree

The valve core and choke coil are made of high wear-resistant hard alloy, which can resist corrosion and corrosion for a long time.

Open indicator and safety lock release device

Equipped with a pressure relief valve

JFK needle type throttle valve and JFG positive type throttle valve are interchangeable on the valve body of the same size.

Cartridge Choke Valve

Used for choke and kill header to control casing pressure during drilling operations.

Convenient flow adjustment and stable flow.

The stem seal is made of special materials, with good chemical stability and corrosion resistance.

The valve core and choke coil are made of high wear-resistant hard alloy, which can resist corrosion and corrosion for a long time.

Barrel gate, the annular gap between the gate and the valve seat, the inlet and the outlet are always connected, mainly used for throttling manifolds or other high-pressure pipelines

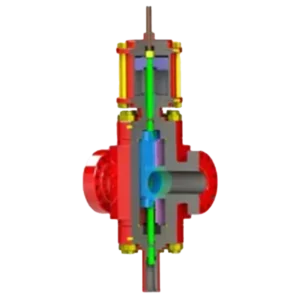

Throttle type Choke Valve

Mainly suitable for drilling, fracturing, mud circulation and onshore high pressure gas injection/production. During the closing process, the pressure difference between the inlet and the outlet pushes the two holes tightly towards each other for sealing and cutting.

If the pressure changes suddenly, the valve can be automatically closed by preset high and low pressure sensors.

Equipped with upper and lower orifices. The opening of the orifice can be controlled by rotating the hand wheel. The orifice plate uses cemented carbide to increase corrosion resistance and corrosion resistance. This valve can be used as a shut-off valve.

Allows a smooth throttle curve.

The inner hole of the outlet has an extended wear-resistant bushing to extend the service life.

The pipe head adapter on the outlet can be replaced according to different pressure conditions.

The stem seal is made of special materials, which can provide good chemical stability and corrosion resistance for the medium.

Cage Choke Valve

The cage design allows fluid to flow along the centerline of the cage, avoiding corrosion and corrosion of choke components and reducing noise.

The choke coil components are made of tungsten carbide carbide to provide a wide choke coil, low noise and excellent corrosion resistance.

Metal to metal seal, easy to maintain

The annular space helps reduce corrosion to the human body.

Low on/off torque, stable operation

Convenient flow adjustment and stable flow curve.

The stem seal is made of special materials, which can provide good chemical stability and corrosion resistance for the medium.

The valve core and choke coil are made of high wear-resistant hard alloy, which can resist corrosion and corrosion for a long time.

Want to Know More Detail About This Drilling Equipment?

相关产品

-

Well Head

Hydraulic Gate Valves

-

Well Head

Weldneck Flange

-

Well Head

Blind Flange

-

Fishing Tools

Float Valve SUB