In the world of oil and gas drilling, efficiency and safety are paramount. One tool that plays a crucial role in ensuring both is the power tong. If you’re in the industry or looking to improve your operations, understanding what a power tong is and how it can benefit your business is essential.

A power tong is a hydraulic or pneumatic device designed to make up (tighten) or break out (loosen) the connections between pipes, especially in drilling operations. It is essentially a large, powerful wrench that can exert significant torque to manipulate drill pipes, casing, or tubing. Power tongs are commonly used in oil and gas drilling to ensure that connections are secure, and they reduce the time and labor required for pipe handling.

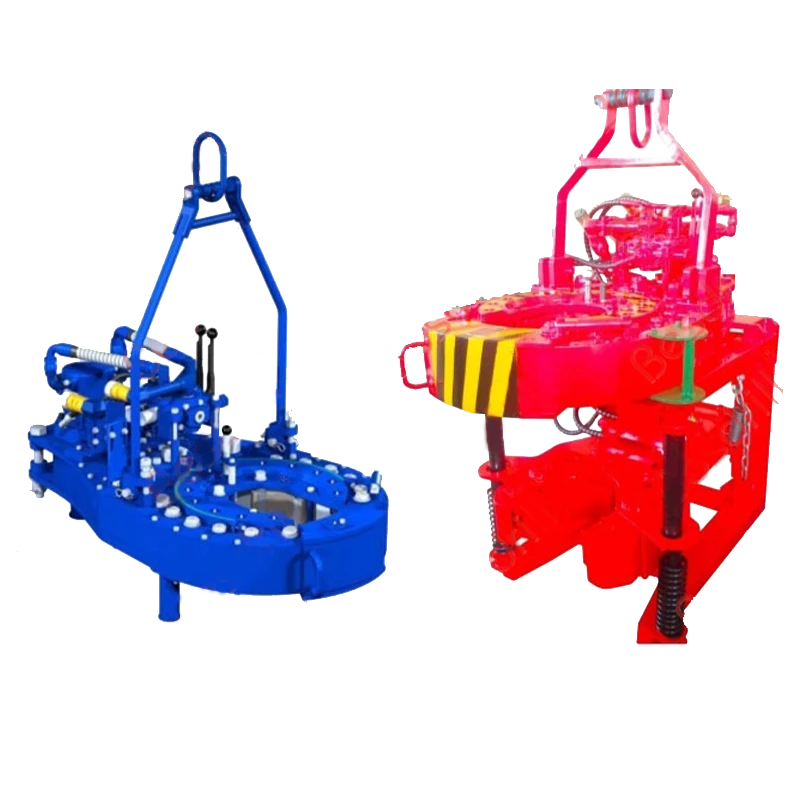

There are different types of power tongs, tailored to various sizes and types of pipes, but they all serve the same purpose: to efficiently and safely handle the joining and disassembly of threaded pipe connections.

Why is a Power Tong Important?

Efficiency and Speed One of the main advantages of power tongs is their ability to save time. In drilling operations, time is money, and any tool that can reduce downtime or speed up the process is valuable. Power tongs can tighten or loosen connections far more quickly than manual tools, allowing for faster drilling, casing, or well servicing. This translates to fewer delays, more productive hours, and ultimately, better profitability.

Safety In high-pressure drilling environments, safety is a top concern. Manual tools can be dangerous when handling heavy pipes or applying significant force. Power tongs are designed to reduce the physical strain on workers, minimizing the risk of injury. With automated controls and precision torque settings, power tongs help ensure that the correct amount of force is applied, avoiding over-tightening or accidents.

Consistency Power tongs deliver consistent results. Human error is reduced when using these machines because they apply the same torque to each connection. This uniformity is critical in drilling operations, where improperly tightened or over-tightened connections can lead to equipment failures or blowouts. A properly functioning power tong ensures that every connection is secure, enhancing operational integrity and safety.

Cost-Effectiveness While power tongs may represent a higher upfront investment compared to manual tools, the long-term cost savings are substantial. The increased efficiency, reduced downtime, and minimized labor costs quickly pay for the equipment. Moreover, fewer incidents of pipe damage or improper connections mean that equipment lasts longer, saving on replacement costs and maintenance.

Versatility Modern power tongs come in various sizes and configurations, making them suitable for different pipe sizes and types.Whether you’re handling drill pipe, casing, or tubing, there’s likely a power tong designed for your specific needs.This versatility makes them an essential tool for many drilling operations, from land-based rigs to offshore platforms.

Types of Power Tongs

There are several types of power tongs available, each suited to different aspects of drilling and well servicing:

Casing Tongs: Designed specifically for handling the larger and heavier casing pipes used in oil and gas wells. They offer high torque to ensure that these large-diameter pipes are securely connected.

Tubing Tongs: These are used for smaller-diameter tubing, such as those involved in well completion and servicing operations.

Drill Pipe Tongs: As the name suggests, these are for drill pipes, offering high precision and torque control during drilling operations.

Each type of power tong comes with customizable features such as automated controls, safety interlocks, and torque monitoring, ensuring that you get the best performance for your specific application.

Innovations in Power Tong Technology

Advances in power tong technology have significantly improved their performance and usability. Some modern power tongs now include digital torque control systems that allow operators to set precise torque limits, preventing over-tightening or under-tightening of connections.

Additionally, many power tongs now feature automated operations, meaning less manual intervention is required. Operators can control the entire make-up or break-out process from a control panel, further enhancing safety and efficiency.These innovations make power tongs indispensable in modern drilling operations.

Why You Should Consider Investing in Power Tongs

If your business is in the oil and gas sector, especially in drilling operations, investing in high-quality power tongs can bring numerous advantages. Their ability to streamline processes, enhance safety, and improve consistency can make a significant difference in your operational efficiency. The long-term cost savings, coupled with fewer accidents and downtime, make them a smart investment for any drilling operation.

Power tongs are essential tools in the oil and gas industry, offering efficiency, safety, and consistency that manual tools simply cannot match. By automating the pipe handling process, they minimize human error and ensure that your operations run smoothly and safely. With advancements in technology, today’s power tongs offer even greater precision and versatility, making them an indispensable part of modern drilling operations. If you’re looking to boost your operation’s productivity and safety, investing in a reliable power tong is a strategic move.