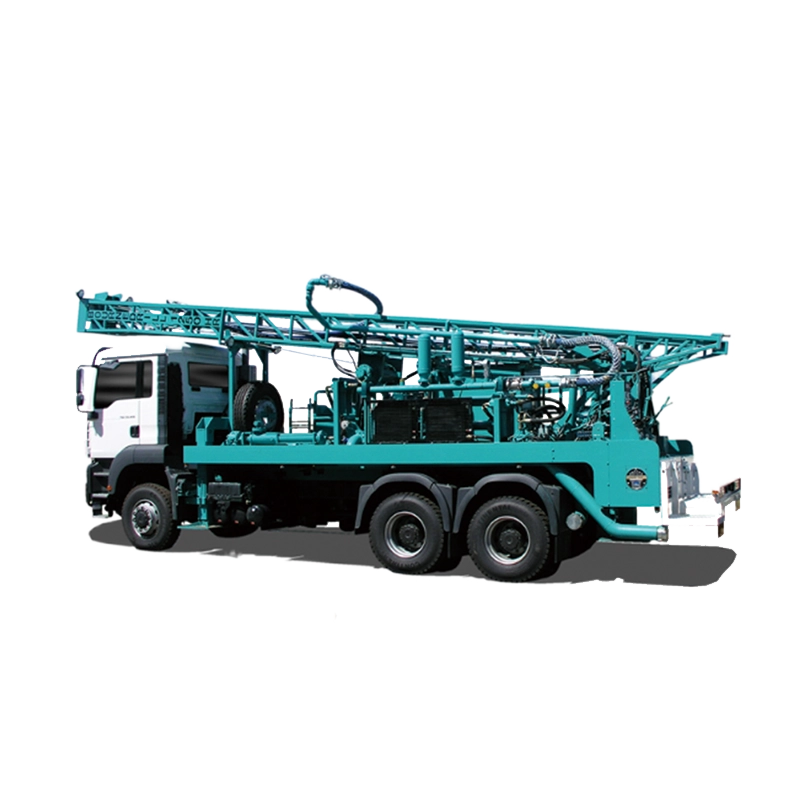

Drilling rigs play a crucial role in the extraction of oil and natural gas from beneath the Earth’s surface. These complex structures are designed to bore holes deep into the ground, facilitating the extraction of valuable resources. While the specific design of drilling rigs can vary significantly based on the type of operation and geological conditions, there are three main components that are essential to all drilling rigs: the drilling structure, the power system, and the circulation system.

1.The Drilling Structure

The drilling structure is the heart of any drilling rig. It consists of several key elements, including the derrick or mast, which is a tall framework that supports the drilling equipment and provides the necessary height for the drill string. The derrick is typically made from steel and is designed to withstand the stresses associated with drilling operations.

At the top of the derrick is the crown block, which contains pulleys and a hoisting mechanism that helps raise and lower the drill string. The drill string itself is made up of multiple sections of drill pipe, which can be extended as the well gets deeper. At the end of the drill string is the drill bit, which is the cutting tool that penetrates the rock formations.

The drilling structure also includes a rotary table or top drive system that enables the drill bit to rotate. This rotation is essential for effectively cutting through the earth’s layers, allowing for the progress of the drilling operation.

2.The Power System

The power system of a drilling rig provides the necessary energy to operate the various components of the rig. This system usually includes a combination of engines, generators, and electrical systems. In many modern rigs, the power is generated by diesel engines that drive generators to produce electricity. This electricity powers the motors that drive the hoisting system, the rotary table, and other equipment on the rig.

In addition to traditional power sources, there has been a growing trend toward utilizing renewable energy sources to enhance the sustainability of drilling operations. Some rigs are now incorporating solar panels or wind turbines to supplement their energy needs, thereby reducing their reliance on fossil fuels and lowering their overall carbon footprint.

3.The Circulation System

The circulation system is a critical component of the drilling rig, responsible for the movement of drilling fluid, commonly known as mud, throughout the drilling process. The primary function of drilling mud is to lubricate and cool the drill bit, remove cuttings from the wellbore, and maintain pressure to prevent blowouts.

The circulation system typically includes a mud pit, which stores the drilling fluid, a pump that circulates the fluid, and various valves and hoses that control its flow. As the drill bit penetrates deeper into the ground, the cuttings produced are carried back to the surface by the circulating mud. This process not only cleans the wellbore but also helps stabilize the walls of the hole, preventing collapses.

The composition of drilling mud can vary depending on the specific conditions encountered during drilling. It may be water-based, oil-based, or even synthetic, depending on the requirements of the well and the geological formations being drilled.

In summary, the three main components of a drilling rig—the drilling structure, power system, and circulation system—work together to ensure the efficient and safe extraction of oil and gas resources. Each component plays a vital role in the drilling process, and advancements in technology continue to enhance their performance and sustainability. As the demand for energy grows, understanding these components becomes increasingly important in the quest for efficient resource extraction.