When it comes to pumping systems, understanding the difference between a sludge pump and a mud pump is essential for choosing the right equipment for your specific needs. Both play a crucial role in various industries, from construction and mining to oil and gas, but they are designed to handle different types of materials and applications. Let’s dive into the key differences and discover the unique features that make these pumps indispensable.

What is a Sludge Pump?

A sludge pump is designed for handling thick, semi-solid materials, often containing a mixture of water, waste, and suspended solids. Sludge is commonly found in sewage treatment plants, industrial waste management, and chemical processing facilities. Sludge pumps are engineered to move materials with higher viscosity and varying particle sizes. These pumps often come with specialized features like agitators to prevent clogging and ensure smooth operation.

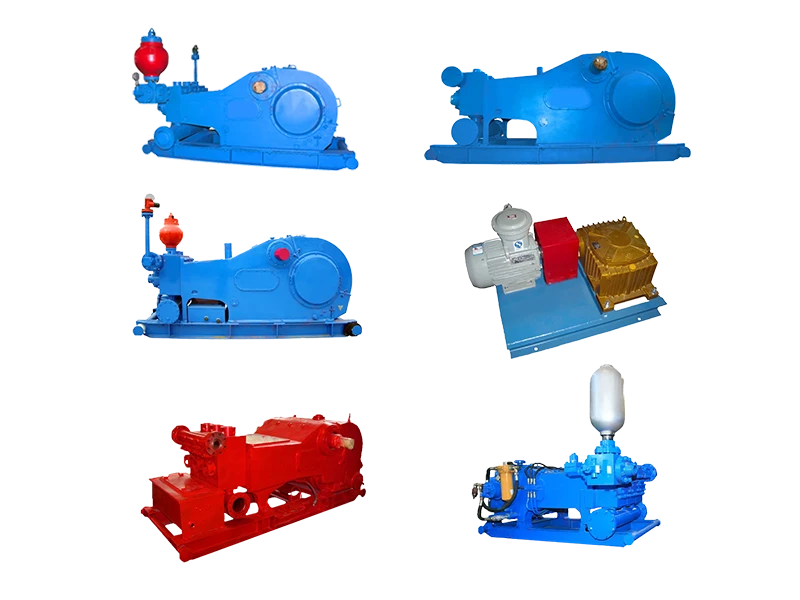

What is a Mud Pump?

On the other hand, a mud pump is primarily used in the drilling and mining industries to circulate drilling fluids or “mud. “Mud pumps are essential for the extraction of resources from deep within the earth, including oil and natural gas. These pumps are designed to handle high-pressure fluids with a high concentration of suspended particles, like clay, water, and other additives. Mud pumps are robust and built to withstand the demanding conditions of drilling operations.

Application:

Sludge Pumps: Primarily used in waste management, sewage treatment, and industrial settings where thicker, more viscous liquids need to be handled.

Mud Pumps: Used in the drilling industry, primarily for circulating drilling mud in oil and gas drilling rigs.

Design Features:

Sludge Pumps: Often feature larger suction capabilities, and may include agitators to prevent clogging. They are made to handle thick, viscous materials with a wide range of particle sizes.

Mud Pumps: Built for high pressure and continuous operation, designed to handle high-density fluids containing solids like sand and clay.

Durability and Maintenance:

Sludge Pumps: Require less frequent maintenance but need to handle abrasive and sometimes corrosive materials.

Mud Pumps: Built for high wear resistance to cope with abrasive mud, requiring regular maintenance to ensure consistent performance.

Why Choose Our Sludge and Mud Pumps?

Innovative Design: Our sludge and mud pumps are engineered with cutting-edge technology, ensuring maximum efficiency and reliability in even the toughest conditions.

Durability: Made from high-quality materials, our pumps are built to last, providing excellent service in harsh environments like drilling operations or industrial waste management facilities.

Versatility: Whether you need a pump for handling thick sludge or circulating drilling mud, we offer a wide range of solutions tailored to meet your exact needs.

Cost-Effective: With low maintenance costs and long service life, our pumps deliver outstanding value for money, ensuring your operations run smoothly without frequent breakdowns or repairs.

Custom Solutions: We understand that every job is unique, which is why we offer custom pump solutions designed to meet your specific requirements. Whether you’re dealing with high viscosity sludge or abrasive drilling mud, we have the right pump for you.

By understanding the specific needs of your operation, you can select the perfect pump to improve productivity, reduce downtime, and enhance overall efficiency. Explore our range of sludge and mud pumps today, and experience the difference in performance, reliability, and cost-effectiveness!