Mud pumps are essential equipment in drilling operations, but like all machinery, they come with their own set of challenges. Over time, these pumps can experience wear and tear, leading to decreased efficiency, higher maintenance costs, and operational downtime. So, what exactly is the problem with mud pumps, and how can it be resolved?

Premature Wear and Tear Mud pumps operate in harsh conditions, circulating drilling fluid that can be abrasive. The continuous pressure and flow can lead to the wear of key components like pistons, liners, and valves.Premature wear causes reduced performance, leading to increased maintenance needs and, ultimately, unscheduled downtime.

Overheating and Lubrication Failures Inconsistent lubrication or improper maintenance can lead to overheating. Mud pumps operate at high speeds and pressures, and without proper cooling and lubrication, the components are at risk of damage.This can cause breakdowns and extend repair times, affecting the entire drilling operation.

Efficiency Losses As mud pumps age, their efficiency decreases. This is often due to worn-out seals, valves, or pressure losses in the system. Inefficient pumps consume more power, increase operational costs, and reduce overall productivity.

Maintenance and Parts Availability While most mud pumps are designed for durability, their maintenance requires access to specialized parts and skilled labor.In many cases, waiting for replacement parts or technicians can lead to unnecessary delays. In remote drilling locations, this becomes even more of a challenge.

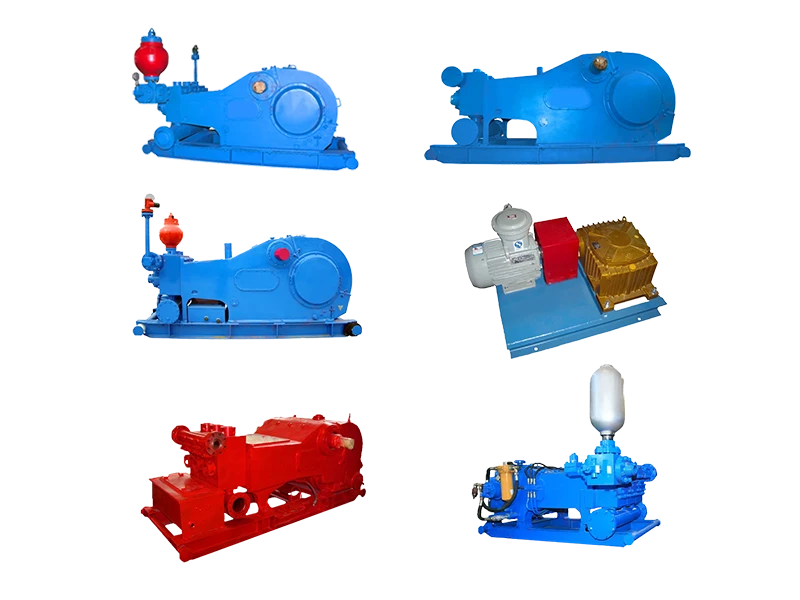

Durability and Long-Lasting Components Our mud pumps are equipped with high-performance, wear-resistant parts that can withstand the toughest drilling conditions. From ceramic-coated liners to advanced piston seals, these features extend the lifespan of the pump, minimizing the frequency of repairs and downtime.

Optimized Efficiency Our pumps are engineered for superior efficiency, with a streamlined design that reduces energy consumption.You’ll benefit from lower fuel and power costs, as well as a more reliable flow rate for your drilling fluid.

Advanced Cooling and Lubrication Systems With a built-in, self-regulating cooling and lubrication system, our mud pumps ensure consistent operation at optimal temperatures.This reduces the risk of overheating, preventing mechanical failures and boosting pump longevity.

Easy Maintenance and Fast Parts Availability We know that downtime is costly. That’s why we’ve made our pumps easy to service and maintain. The modular design allows for quick part replacements, and our network ensures that the necessary parts are readily available, even in remote locations.

Cost-Effective Performance Our mud pumps offer high-performance without breaking the bank. With reduced energy consumption, extended lifespan, and lower maintenance costs, they provide excellent ROI for any drilling operation.

Why Choose Us?

Investing in the right mud pump is crucial for maintaining the smooth operation of any drilling project. With our state-of-the-art mud pumps, you can expect fewer breakdowns, reduced operational costs, and improved efficiency.