Looking for a Reliable and Cost-Effective Drilling Pump?

In water well and geothermal drilling projects, a dependable mud pump plays a critical role in ensuring circulation efficiency and borehole stability. For mid-depth operations that require steady performance, the W446 Triplex Mud Pump stands out as one of the most popular and budget-friendly choices in the drilling equipment market.

W446 Mud Pump Overview

The W446 pump is a triplex single-acting horizontal reciprocating pump, widely used in water well drilling, geothermal borehole construction, shallow oil & gas exploration, and mineral investigations.

Key Specifications

| Parameter | Value |

|---|---|

| Pump Type | Triplex single-acting horizontal pump |

| Stroke Length | 6 inches (approx. 152 mm) |

| Flow Rate | 160–250 L/min |

| Pressure Range | 3–5 MPa |

| Power Requirement | 55–75 kW (depending on configuration) |

| Drive Options | Diesel engine / Electric motor |

| Application Fields | Water wells, geothermal drilling, CBM |

Why Choose the W446 Mud Pump?

Durable and Easy to Maintain

The W446 uses standardized parts (pistons, valves, liners) that are widely available and easy to replace, making it ideal for field use.

Compatible with Multiple Power Sources

Whether you’re operating on diesel engines, electric motors, or belt drives, the W446 adapts easily to various power systems.

Excellent Cost-Performance Ratio

Compared to larger or more complex pumps, the W446 offers reliable performance at a significantly lower upfront and operating cost.

Field-Tested Across Multiple Applications

Trusted by drillers in rural water supply, geothermal fields, and shallow resource exploration.

Common Applications of the W446 Pump

| Application Area | Use Case Examples |

|---|---|

| Water Well Drilling | Borehole flushing, rural & municipal wells |

| Geothermal Drilling | Circulation support for closed-loop systems |

| CBM & Gas Drilling | Low-pressure fluid circulation |

| Mineral Exploration | Mud support for soil & rock sampling |

Main Components & Construction

- Crankshaft – Forged for high load-bearing capacity

- Piston Assembly – Wear-resistant rubber, easily replaceable

- Valve Assembly – Steel wing-guided valve + rubber seat for better sealing

- Lubrication System – Splash or forced lubrication ensures smooth operation

- Pump Body – Integrated cast housing with high pressure resistance

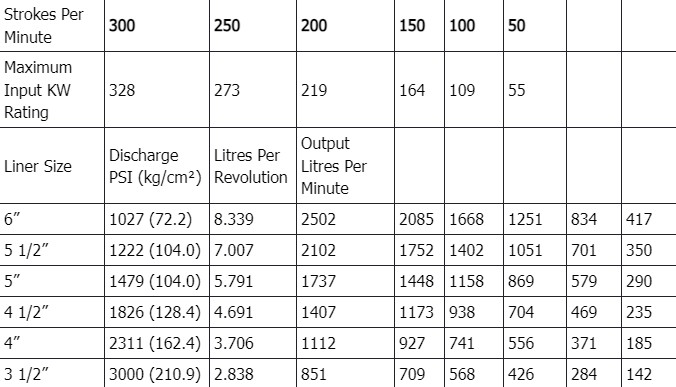

Technical Specifications

Choosing the Right Liner Size for Your Project

| Drilling Type | Recommended Liner | Target Flow | Ideal Power Source |

|---|---|---|---|

| Shallow water wells | 6” | High flow | 55 kW electric |

| Geothermal drilling | 5”–5.5” | Balanced | 65 kW diesel |

| CBM shallow drilling | 4.5” | Higher pressure | 75 kW engine |

Common Issues & Troubleshooting

Q1: Unstable mud output?

→ Check for worn-out valves or air suction at the inlet.

Q2: Can W446 work in mountainous or remote areas?

→ Yes, its compact size and flexible power options make it ideal for field operations.

Q3: Is it suitable for trailer-mounted rigs?

→ Absolutely. The pump is frequently used with mobile drilling units.