Introduction: Why Downhole Fishing Safety Matters

In oil and gas drilling operations, downhole fishing refers to the retrieval of stuck, lost, or broken equipment from the wellbore. Though common, fishing operations can be highly hazardous if not managed with precision and adherence to industry standards.

To mitigate risks, the American Petroleum Institute (API) developed the Recommended Practice 54 (API RP 54)—a comprehensive guideline that outlines safe practices for well servicing and workover operations, including fishing.

For companies like BESDRILL, which manufacture and supply high-performance fishing tools, compliance with API RP 54 is both a safety mandate and a mark of professionalism.

What is API RP 54?

API RP 54 is titled “Occupational Safety and Health for Oil and Gas Well Drilling and Servicing Operations.” It establishes best practices and minimum safety requirements for personnel, equipment, and procedures used in drilling, completion, servicing, and intervention operations, including:

- Rig and rig floor safety

- Personal protective equipment (PPE)

- Handling of hazardous substances

- Fall protection

- Emergency response

- Specialized operations such as fishing, snubbing, coiled tubing, and wireline

The latest revision (2023) includes updates for automation, digital monitoring, and enhanced fall protection strategies—elements increasingly relevant in modern fishing environments.

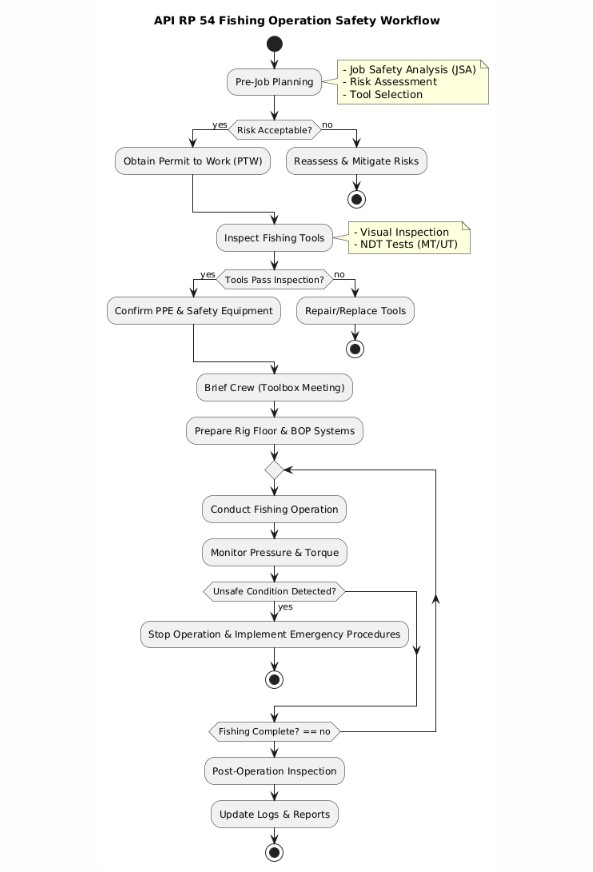

API RP 54 Safety Requirements for Downhole Fishing

Downhole fishing introduces a unique set of hazards, including sudden pressure surges, dropped objects, rotational equipment risks, and confined space exposure. API RP 54 addresses these risks in several ways:

1. Pre-Job Planning and Risk Assessment

- Conduct thorough job safety analysis (JSA) specific to the fishing scenario.

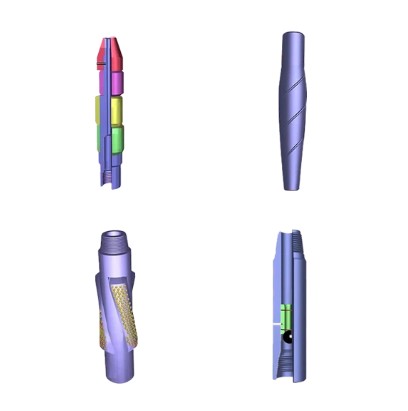

- Include tool specifications (e.g., overshot, spear, bumper sub) in the operation plan.

- Evaluate well pressure, fluid type, and potential blowout risks.

2. Equipment Integrity & Inspection

- Fishing tools must be certified, tested, and regularly inspected.

- BESDRILL fishing tools, for instance, comply with international NDT (Non-Destructive Testing) protocols to ensure steel integrity and thread connection reliability.

3. Rig Floor Safety

- Maintain clean, non-slippery surfaces.

- All rotating fishing equipment must have adequate guards.

- Pipe-handling equipment must have emergency shut-off systems.

4. Pressure Control and Well Monitoring

- API RP 54 mandates proper use of BOP (Blowout Preventer) systems during fishing.

- Fishing operations must include real-time monitoring of annular pressure, fluid returns, and tool depth.

5. Personal Protective Equipment (PPE)

- Mandatory PPE includes flame-resistant clothing, face shields, anti-slip gloves, and metatarsal boots.

- Specialized PPE like impact-resistant hard hats is required when handling jars or pulling heavy tools from the hole.

6. Communication and Supervision

- Establish clear command hierarchy on-site.

- Use standardized hand signals and communication systems, especially during tripping and jarring operations.

Case Study: Safe Fishing with BESDRILL Tools

In a recent offshore operation in Southeast Asia, a BESDRILL overshot assembly was used to retrieve a sheared drill string at 1,800 meters depth. Following API RP 54 guidelines:

1.A pre-job risk analysis was conducted involving both rig and BESDRILL personnel.

2.Dual check valves and high-strength elevator links were used.

3.Real-time torque and drag monitoring systems helped avoid tool overloading.

4.No injuries or NPT (non-productive time) were reported.

This operation highlights how standard-compliant equipment and procedures contribute directly to safety and efficiency.

Why API RP 54 Compliance is Essential for Fishing Tool Suppliers

If you’re selecting a fishing tool supplier, it’s crucial they operate within the framework of API RP 54. Here’s why:

- Reduces liability and insurance premiums

- Ensures equipment reliability under high-pressure environments

- Enhances crew confidence and coordination

- Promotes longer tool life and fewer failures

BESDRILL ensures that all downhole fishing tools—spears, overshots, magnets, jars, and more—are manufactured with API-compliant steel grades and surface treatments, offering both safety and performance.

Conclusion

Downhole fishing operations are inherently high-risk, but adherence to API RP 54 significantly reduces those risks. From rig floor safety protocols to pressure control and tool inspection routines, this standard is a critical reference for any operation involving fishing tools.

If you’re seeking API RP 54-compliant fishing tools, BESDRILL offers a full portfolio designed to meet your technical and safety requirements.

Visit our product page for more about BESDRILL Fishing Tools 🔧 or consult the full API RP 54 Guideline 📜.