When it comes to controlling the flow of fluids in high-pressure environments like oil drilling rigs, natural gas pipelines, or underground water systems, the reliability of a valve is not just a matter of efficiency — it’s a matter of safety. One valve type stands out in these critical applications: the Expanding Gate Valve.

But what exactly is an expanding gate valve? And why is it gaining increasing attention in today’s drilling and pipeline operations? Let’s break it down.

What Is an Expanding Gate Valve?

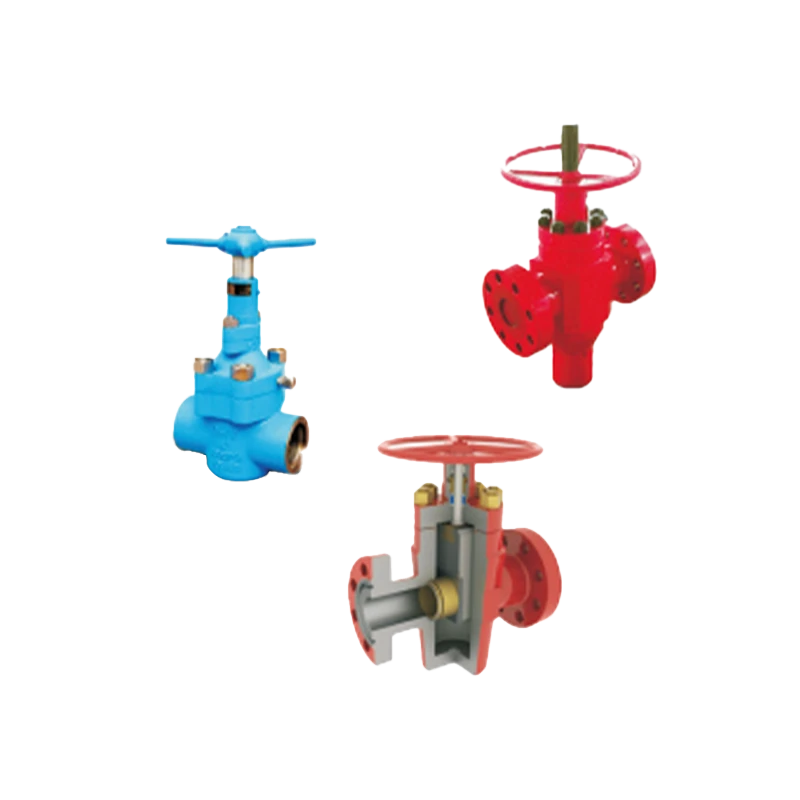

An expanding gate valve is a special type of slab gate valve designed to achieve a tight mechanical seal through the expansion of its internal gate mechanism. Unlike standard gate valves that rely mostly on line pressure or soft seals, the expanding gate valve has a two-piece wedge mechanism that expands during operation, pressing tightly against both the upstream and downstream seats.

This design ensures a solid, bi-directional seal, even in low-pressure or zero-pressure conditions—something standard valves can’t always guarantee.

How It Works: The Smart Seal Mechanism

The core of the expanding gate valve lies in its sliding and wedging components. When the valve is closed, the two gate halves are forced outward, locking against the seat rings. This creates a mechanical seal independent of the fluid pressure. When opened, the gates retract smoothly, minimizing wear on the seat and gate surfaces.

This intelligent mechanical action offers two huge advantages:

- Reliable shutoff regardless of pressure

- Reduced risk of erosion or seat damage

Why It Matters in Drilling and Pipeline Systems

In drilling rigs and pipeline networks, valves are constantly exposed to abrasive fluids, pressure fluctuations, and corrosive environments. A minor leak or malfunction can cause downtime, environmental hazards, or even catastrophic failure.

Here’s why expanding gate valves are preferred in such conditions:

✅ Bi-directional Sealing

Seals effectively in both flow directions — crucial in complex pipeline networks.

✅ Low Operating Torque

Despite their robust sealing, these valves are surprisingly easy to operate — ideal for remote or automated systems.

✅ No Pressure Dependency

Works just as well in low-pressure or zero-pressure lines — offering more flexibility in system design.

✅ Minimal Seat Wear

Since the seal is mechanical and not solely pressure-based, there’s less friction, leading to longer valve life.

Common Applications

- Oil & Gas Drilling Platforms

With high pressure and dirty fluids, these sites demand valves that won’t quit. - Natural Gas Transmission

Where reliability over long distances and fluctuating flow is vital. - Water Injection Systems

Often low pressure and highly corrosive, these require a different kind of valve resilience. - High-integrity Pipeline Isolation (HIPPS)

Safety-critical systems where leak-proof performance is mandatory.

Is It Right for You?

If your operation deals with frequent shutoffs, variable pressure, or safety-sensitive environments, an expanding gate valve might be the upgrade your system needs.

While they may cost more upfront than traditional gate valves, the long-term reliability, minimal maintenance, and safety benefits make them a smart investment for critical infrastructure.

Conclusion

In modern drilling and pipeline systems, expanding gate valves represent more than just another piece of hardware — they are a smart engineering solution tailored for today’s toughest industrial demands.

Whether you’re in upstream oil production or managing a cross-country gas pipeline, understanding the value of this innovative valve can lead to smarter decisions, safer operations, and better performance across the board.