Popular Flange Styles

Weld Neck Flange

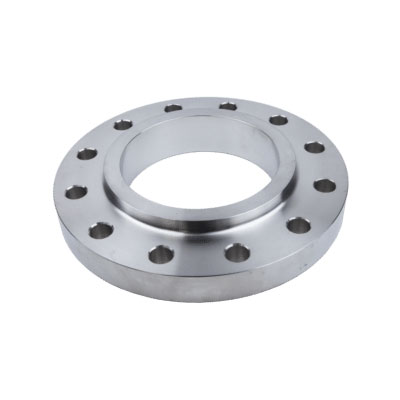

Slip On Flange

Blind Flange

Socket Weld Flange

Orifice Flange

Reducing Flange

Alloy Flange

Butt Welding Flange

Flange Pipe Fittings

Forging Flange

Large Caliber Flange

Neck Alloy Flange

Flat Welding Flange

Pipe Fittings Stainless Steel Flange

Thread Flange Forging Flange

Industries We Serve

What Makes BESDRILL Different

Customer Service

Our customer service team is highly responsive and takes full ownership over every order.

Quality

Products meet customer requirements and quality control is built in throughout our process.

Delivery

The right products are in inventory and shipments arrive on time to meet customer need.

Customization

Modifications can be made to standard parts, or we can manufacture custom parts, to rapidly respond to customer need.

Frequently Asked Questions (FAQs)

A flange connects pipes, valves, pumps, and other equipment to form a pipeline.

A flanged fitting is a pipe connection with a protruding rim (flange) for secure attachment to other components using bolts.

The three most common flange types are Weld Neck Flanges, Slip-On Flanges, and Blind Flanges.

The industry’s most used flange type is the weld neck flange, including long weld necks.