Introduction: Why a By-Pass Valve Matters in Drilling Operations

In complex and high-risk drilling environments, unplanned pressure surges such as kicks, formation fluid influx, or bit nozzle blockages pose serious threats to both equipment and personnel. To ensure safety and maintain well control, bypass valves play a critical role by allowing fluid circulation even when normal flow paths are obstructed.

BESDRILL bypass valves are engineered to handle extreme conditions during oil, gas, and geothermal drilling. This article presents a comprehensive overview of bypass valve applications, mechanisms, specifications, and operational steps to help engineers, buyers, and site supervisors select the right circulation tool for their drilling setup.

What Is a By-Pass Valve in Drilling?

A by-pass valve, also known as a circulation sub or circulating valve, is a safety tool used in bottom-hole assemblies (BHAs). It allows the drilling fluid (mud) to bypass blocked nozzles or flow paths in situations such as:

- Bit nozzle plugging

- Excessive back pressure during well kicks

- Circulation loss or differential sticking

By allowing alternate fluid circulation, the bypass valve enables operators to regain control, kill the well, and resume drilling or well intervention.

How Does the BESDRILL By-Pass Valve Work?

BESDRILL bypass valves operate through a pressure-activated ball drop system. Here’s how it works step by step:

- Ball Release

A steel or nylon ball is dropped into the drill string via the Kelly or top drive. - Ball Seating

Pumping fluid drives the ball down to a precision ball seat inside the bypass valve. - Pressure Activation

When pump pressure rises 0.5–1.5 MPa above normal, a shear pin breaks. - Flow Redirection

The sealing sleeve shifts downward, opening side outlets to create a bypass flow path around the bit. - Circulation Restored

The pressure drops, indicating successful activation. Circulation resumes, and the well can be killed if necessary.

This reliable design ensures that even in critical downhole conditions, BESDRILL’s by-pass valve performs seamlessly.

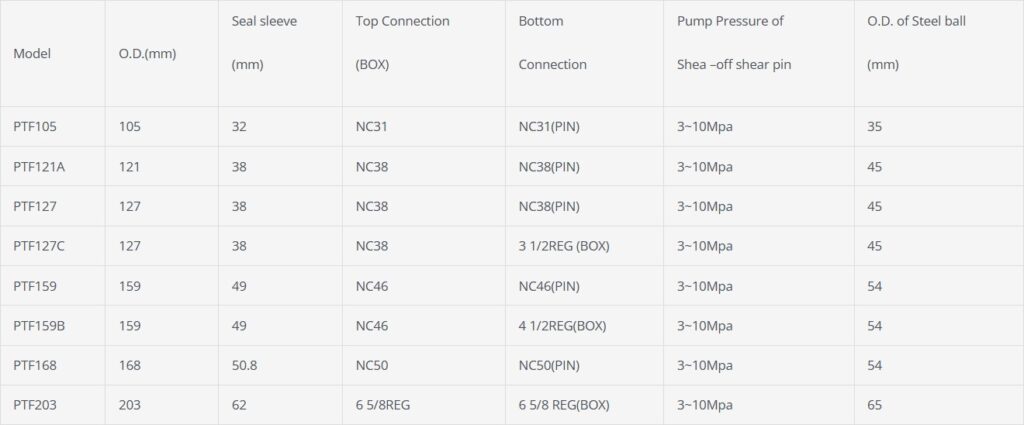

BESDRILL By-Pass Valve Technical Specifications

Note: Custom threads and pressure ratings can be made available upon request.

5 Major Safety Functions of BESDRILL By-Pass Valve

- Well Kick Mitigation

Opens fluid flow when formation pressure surges or backflow occurs. - Bit Plugging Solution

Maintains circulation if the drill bit nozzles are clogged. - Pump Overpressure Relief

Prevents casing and pump damage by activating fluid bypass. - Secondary Circulation Channel

Ensures critical operations such as well killing and mud conditioning can proceed. - Non-Rotating Flow Path

Minimizes wear on internal components by separating rotating and flowing parts.

How to Order the Right By-Pass Valve

When placing an order for a BESDRILL by-pass valve, please specify:

- Outer Diameter (OD) of the tool

- Top and bottom thread connections (NC31, NC38, REG, etc.)

- Desired shear pressure range (if different from standard)

- Special material requirements (e.g., stainless, alloy steel)

BESDRILL supports customization for both API-standard and special drilling environments.

Technical Advantages of BESDRILL By-Pass Valve

- High Strength Alloy Body – Heat-treated for high-pressure applications

- Precision Shear Pin Design – Ensures consistent activation

- Polymer Ball Seat – Corrosion- and erosion-resistant

- Field-Replacement Design – Easy to service and maintain onsite

- Wide Temperature Tolerance – Suitable for both deep wells and surface workovers

These advantages translate into greater drilling reliability, reduced downtime, and operational safety.

Conclusion: Why Choose BESDRILL for By-Pass Valves

The BESDRILL by- pass valve is a robust, pressure-activated circulation solution designed to meet the toughest drilling challenges. With precise engineering, API threading options, and safety-first design, BESDRILL offers unmatched value to drilling contractors worldwide.

The BESDRILL bypass valve is designed in strict accordance with API RP 54 safety standards to ensure safe and reliable well control operations.

Please refer to our BESDRILL product page for details. Choosing the appropriate steel ball ensures smooth activation of the valve.