1. Definition and Working Principle of Drilling Safety Joint

A Drilling Safety Joint is a specialized mechanical connection installed within the drill string, designed to enable controlled emergency disconnection under downhole stuck pipe or abnormal conditions. Its core function is to release the drill string at a predetermined torque or tensile load threshold, preventing tool damage and wellbore blockage, thereby ensuring safe and continuous drilling operations.

BESDRILL safety joints utilize advanced mechanical locking mechanisms combined with high-performance alloy materials to guarantee precise and reliable release performance under complex downhole high-temperature and high-pressure environments.

2. Five Key Technical Advantages of BESDRILL Drilling Safety Joint

2.1 High-Performance Alloy Materials and Heat Treatment of BESDRILL Drilling Safety Joint

BESDRILL Safety Joints are manufactured from internationally standardized 4145H quenched and tempered alloy steel, renowned for its excellent comprehensive mechanical properties—particularly yield strength, tensile strength, and fatigue limit. To further enhance surface wear resistance and corrosion protection, the components undergo multi-stage composite heat treatments including nitriding and carburizing. Nitriding creates a hardened surface layer with significantly improved wear resistance and fatigue life, while carburizing optimizes the depth and gradient of the hardened layer, balancing surface hardness with core toughness. This combination effectively mitigates surface brittleness and crack propagation risks, ensuring exceptional durability and structural integrity under high load and dynamic impact conditions.

Moreover, strict control of quenching temperatures and cooling rates during manufacturing minimizes residual stresses and microstructural defects, maximizing overall product reliability and service life.

For in-depth information on heat treatment processes used in alloy steels, explore resources from 👉ASM International👈.

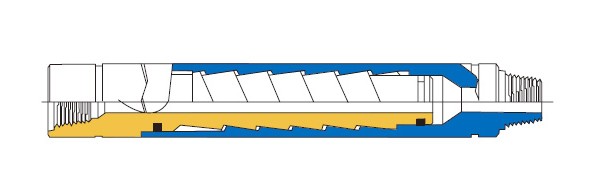

2.2 Precision Mechanical Locking and Release Mechanism in BESDRILL Drilling Safety Joint

The release mechanism of BESDRILL Safety Joints employs a spring-loaded locking pin assembly with adjustable torque release thresholds tailored to specific drilling conditions. Through detailed Finite Element Analysis (FEA), stress distribution within the mechanism is optimized to ensure uniform load transfer, minimizing localized stress concentrations that could lead to fatigue cracks or plastic deformation.

The release operation is designed for smooth, shock-free disengagement, significantly reducing fatigue damage and extending equipment lifespan. High-precision machining ensures tight tolerances and minimal clearance between locking pins and springs, enhancing release responsiveness and reliability. The mechanism supports multiple cycles of disconnection and reset, improving operational versatility and cost efficiency.

2.3 Standardized Multi-Size Design of BESDRILL Drilling Safety Joint

BESDRILL Safety Joints are available in a wide size range from 2 3/8″ to 6 5/8″, comprehensively meeting diverse wellbore diameters and operational requirements. All thread connections strictly comply with API REG (External Round Thread) and IF (Internal Flush) standards, ensuring seamless compatibility with the majority of drill pipes and downhole tools in the market.

During the design phase, careful attention is given to connection dimensional tolerances and sealing performance. High-strength sealing elements and anti-corrosion thread treatments guarantee connection integrity and long-term durability. The standardized design greatly simplifies field logistics, reduces inventory complexity, and lowers operational costs.

2.4 Modular Construction for Easy Maintenance of BESDRILL Drilling Safety Joint

To adapt to the complex and variable conditions of drilling sites, BESDRILL Safety Joints utilize a modular design philosophy. Critical components such as spring assemblies, sealing rings, locking pins, and end caps can be disassembled and replaced independently without requiring full unit replacement.

This approach significantly reduces maintenance expenses and downtime, improving continuous operation on site. Modular construction also facilitates onsite fault diagnosis and wear assessment, enabling more scientific maintenance scheduling. Specialized disassembly tools and comprehensive technical manuals further ensure safe and accurate field servicing.

2.5 Compliance with International API Standards for BESDRILL Drilling Safety Joint

The design, manufacture, and testing of BESDRILL Safety Joints strictly adhere to API RP 7G (Recommended Practice for Drill Stem and Well Control Equipment) and API RP 54 (Safety Practices for Drilling Operations). This compliance guarantees product performance meets the stringent safety requirements of the global oil and gas industry.

The products undergo systematic mechanical performance validations including static and dynamic load testing, fracture toughness evaluation, fatigue life analysis, and corrosion resistance assessments, ensuring stable and reliable operation in demanding downhole environments.

Furthermore, the production process is governed by a comprehensive Quality Management System (QMS) encompassing raw material inspection, critical process control, final product testing, and pre-shipment inspections, assuring that every unit meets or exceeds design specifications and safety standards.

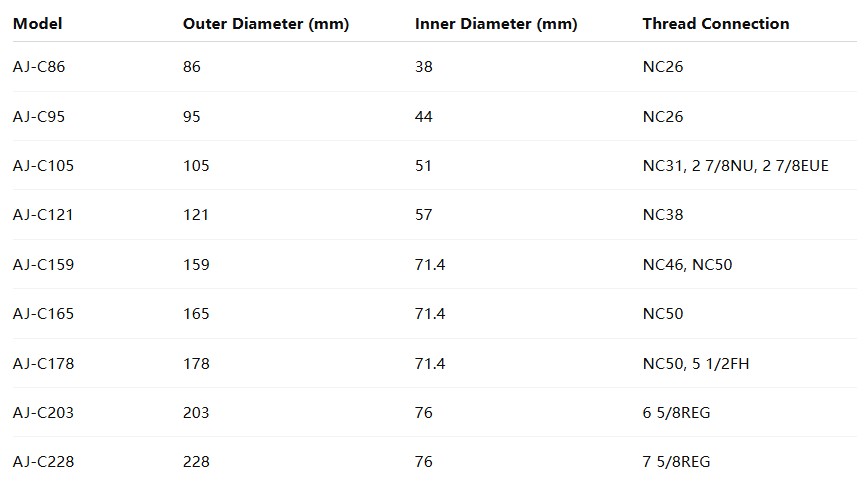

3. Key Technical Specifications of BESDRILL Drilling Safety Joint

Multiple inspection stages ensure dimensional accuracy and structural integrity, guaranteeing controlled and safe release operations.

4. Typical Applications and Field Performance of BESDRILL Drilling Safety Joint

BESDRILL drilling safety joints are built tough to handle many demanding drilling situations, helping to keep your operations running smoothly and safely:

- Oil & Gas Drilling: When the drill pipe gets stuck underground, safety joints let you disconnect the stuck part quickly and safely. This prevents bigger problems, saves time, and avoids costly repairs.

- Geothermal Drilling: Geothermal wells can be super hot and under high pressure. BESDRILL safety joints are made to keep working strong even in these extreme conditions, thanks to their special heat-treated materials and corrosion protection.

- Horizontal Directional Drilling (HDD): HDD puts a lot of twist and strain on the drill string because of the bends and turns. Our safety joints can handle high torque loads repeatedly without breaking down, so your job keeps going.

- Fishing Operations: When you need to retrieve stuck tools (“fishing”), being able to release the drill string fast reduces the chance of damaging other equipment and saves valuable time.

- Offshore Drilling: Saltwater environments can cause parts to rust and wear out quickly. BESDRILL safety joints use corrosion-resistant alloys and coatings designed to last long in these harsh marine conditions.

Real-world projects show BESDRILL safety joints help reduce unexpected stops, protect your gear, and keep your drilling on track no matter where you work.

5. Technical Considerations for Selecting BESDRILL Drilling Safety Joint

Picking the right safety joint isn’t just about size — it’s about matching the joint to your well’s specific needs:

- Match Size and Thread: Make sure the safety joint fits perfectly with your drill pipes. Using the right thread type — like API REG or IF — means better connection strength and sealing.

- Set Proper Release Torque: The joint’s release torque should be a bit higher than your normal operating torque so it doesn’t disconnect too early. But if the drill string really gets stuck, it should release easily without extra force.

- Material Fit for Environment: Think about the downhole temperature, pressure, and corrosive elements. You want materials that won’t crack or corrode quickly, especially for hot geothermal wells or salty offshore sites.

- Easy Maintenance: Choose designs that let you swap out springs, seals, and pins on site without changing the whole unit. That saves time and money and keeps your rig running.

- Get Expert Advice: Every drilling site is different. BESDRILL’s engineers can help customize your safety joint — from torque settings to materials — making sure it matches your exact needs and keeps your operation safe and efficient.

Talking with our team early means you get the right gear from the start, avoiding surprises and costly downtime down the road.

Choose BESDRILL Drilling Safety Joint to leverage advanced materials and mechanical engineering, providing scientifically proven, efficient, and safe disconnection protection for your drilling operations!

The detailed specifications and technical parameters of this product can be found on our 👉Safety Joint Product Page👈.