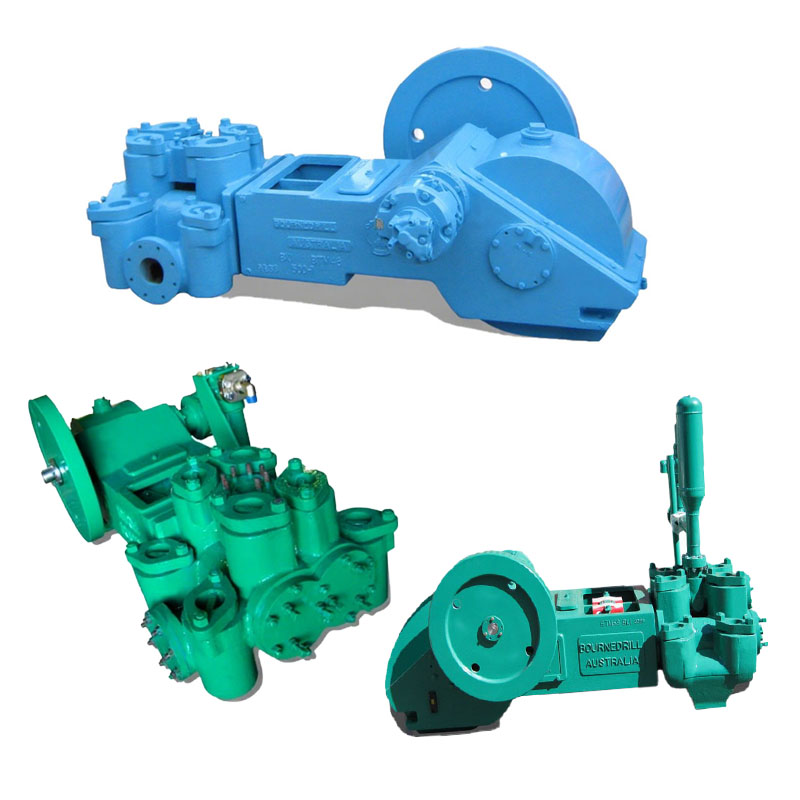

In demanding drilling environments, a reliable and efficient mud pump is essential to ensure smooth operation. The BESDRILL GD Series Duplex Mud Pump, a high-performance reciprocating pump, is specially designed to meet the needs for high pressure and large flow fluid delivery in water well drilling, mining, and geological exploration. This article will analyze the six core advantages of the GD series duplex mud pump from structure, performance, application, and benefits, helping users choose the right pump and ensuring project success.GD Series Duplex Mud Pumps have become an industry benchmark in efficient fluid delivery systems.

1. Overview of GD Series Duplex Mud Pumps: High Adaptability in the Field

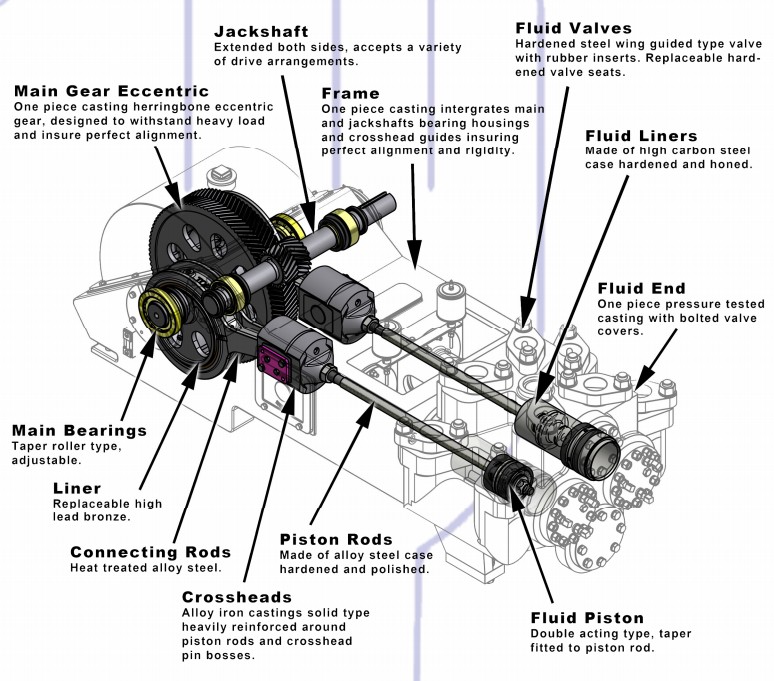

The BESDRILL GD series features a duplex symmetrical design, equipped with polished alloy piston rods, replaceable high-strength carbon steel liners, and hardened fluid end components. It offers high efficiency, stability, and ease of maintenance. Widely applied in geological survey, hydrological drilling, environmental engineering, and open-pit mining projects.

With optional power configurations including diesel, electric, and belt drive, this series provides excellent adaptability and customization, making it the preferred pump for field construction teams.

2. 6 Key Technical Advantages of GD Series Duplex Mud Pumps

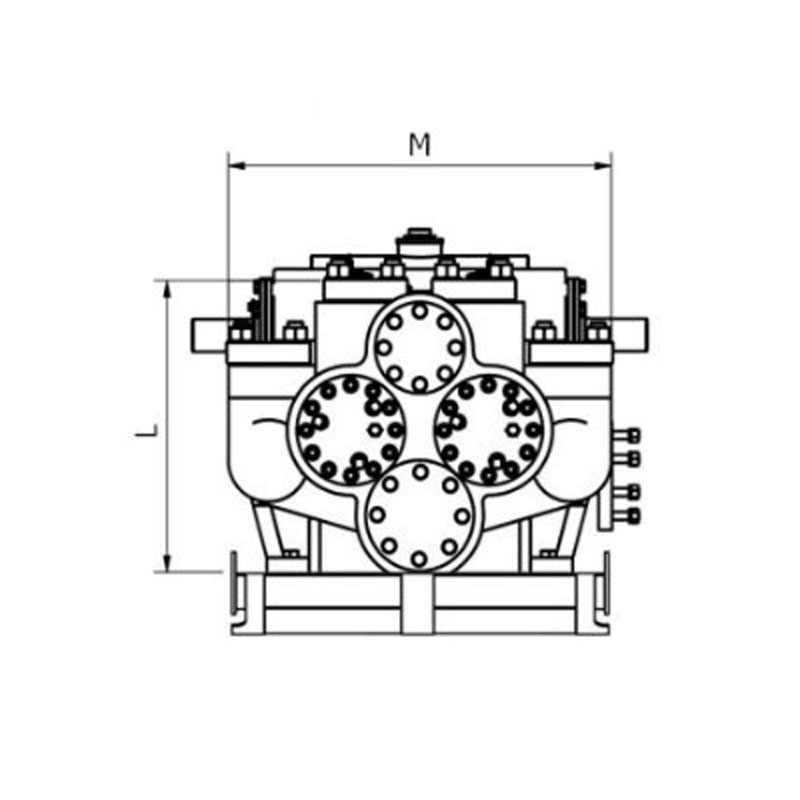

1. Stable and Reliable Flow Output (Duplex Design)

The GD series uses a duplex reciprocating opposed cylinder structure, significantly reducing fluid output pulsation. Compared with single-cylinder pumps, duplex pumps deliver high flow while maintaining smooth pumping, effectively protecting downstream pipelines and equipment.

For example:

- Model P6 achieves a maximum flow of 757 LPM with stable pulsation

- Model P10-7½ can provide continuous fluid delivery up to 2411 LPM

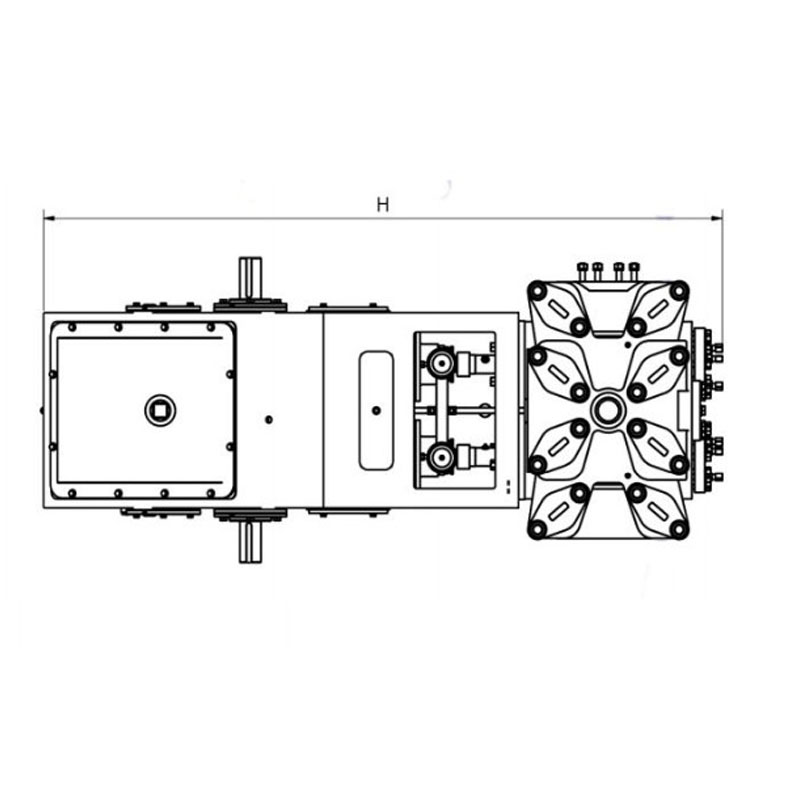

2. Robust and Durable Structural Design

Structural components such as gears, crossheads, connecting rods, and bearings use high-strength alloy materials and undergo heat treatment, offering excellent fatigue resistance and load capacity.

- Main gear features a herringbone eccentric gear design for smooth transmission and low noise

- Piston rod load capacity up to 5,112 kg, suitable for heavy-duty operations

- Integrated frame structure ensures long-term coaxial alignment and vibration resistance

3. Highly Compatible Parts Supporting OEM Standards

GD pump parts are fully compatible with mainstream API mud pump spare parts standards, supporting OEM interchangeability for easy local sourcing and fast maintenance.

Examples:

- Replaceable rubber insert pistons

- Hardened fluid valve seats and assemblies

- Support standard pressure filter oil and high-pressure seals replacement

4. Flexible Drive Options for Strong Adaptability

Depending on worksite conditions, GD series pumps can be driven by:

- Diesel engine for remote, off-grid operations

- Electric motor for stable and environmentally friendly operation

- Belt drive suitable for small drilling rigs and linked equipment

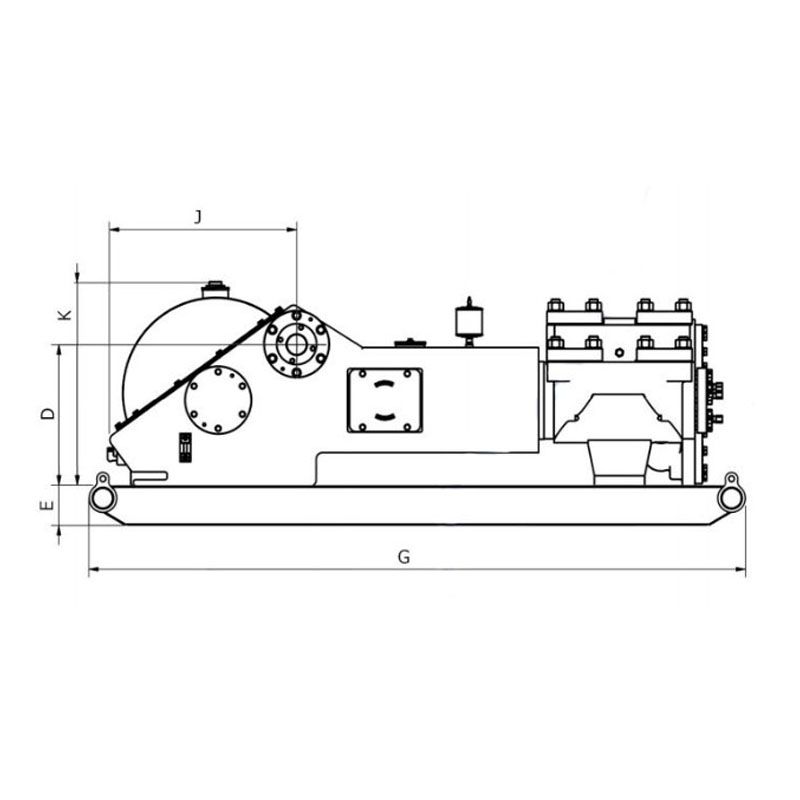

5. Simple Maintenance and Fast Parts Replacement

- Modular design for wear parts like pistons, liners, and valve seats allows quick replacement without dismantling the entire pump

- Extended jackshaft and external lubrication systems enable easier bearing adjustment and maintenance

- All wetted fluid end parts made from high-carbon steel or bronze for excellent wear resistance

6. Rich Parameter Options to Meet Various Operation Needs

| Model | Stroke (inch) | Liner Diameter (mm) | Max Flow (LPM) | Max Pressure (PSI) | Piston Rod Load (kg) |

|---|---|---|---|---|---|

| P5-4 | 4.0 | 101.6 | 435 | 250 | 1,424 |

| P6-5 | 5.0 | 127.0 | 757 | 310 | 2,777 |

| P8-5½ | 5.5 | 139.7 | 1200 | 730 | 3,645 |

| P8-7½ | 7.5 | 190.5 | 2271 | 75 | 3,645 |

| P10-5½ | 5.5 | 139.7 | 1276 | 109 | 5,112 |

| P10-7½ | 7.5 | 190.5 | 2411 | 111 | 5,112 |

Users can flexibly match pump models based on drilling depth, rock formation, and fluid properties to ensure efficient and economical operation.

3. Where GD Series Duplex Mud Pumps Are Used

- Deep Well Drilling & Geothermal Survey: Stable operation in high-pressure zones over 2000 meters depth, supporting large flow circulation cooling

- Geotechnical & Environmental Drilling: Suitable for various media such as mud, foam, and cement slurry

- Construction Dewatering & Tunnel Grouting: Compatible with skid-mounted systems for flexible relocation from urban sites to remote areas

Whether used in remote mining areas or urban foundation projects, GD Series Duplex Mud Pumps offer unmatched reliability.

4. Custom Options for GD Series Duplex Mud Pumps

To enhance operational flexibility and safety, BESDRILL offers the following custom accessories:

- Pulsation Dampener: Reduces pulse impact to protect pump head and pipelines

- Safety Relief Valve: Prevents overpressure conditions

- Oilfield-Grade Pressure Gauges: Adapted for harsh field environments

- Steel Skid Base: Facilitates lifting and transport

- Integrated Drive Matching: Supports engine, motor, and hydraulic motor interfaces

Conclusion: A Reliable Choice Among Duplex Pumps

With high-strength structural design, flexible power adaptability, easy maintenance, and outstanding pumping performance, the BESDRILL GD series duplex mud pump has become the preferred equipment for many drilling contractors. Whether in challenging mining areas or urban infrastructure projects, the GD series offers dependable support.Choose GD Series Duplex Mud Pumps by BESDRILL for long-lasting performance and superior maintenance ease.

📌 Recommended Reading: Top 5 Causes and Prevention of Mud Pump Bearing Failure

🔗 External Resource: API Standards in Oil & Gas Equipment