The BESDRILL lubricated fishing bumper is an essential vibration tool widely used in downhole fishing operations. Featuring an advanced hydraulic lubrication system and scientifically engineered energy conversion design, it delivers strong and stable impact forces, helping you efficiently tackle stuck pipe problems in deep and intermediate wells. For detailed product specifications, visit our Lubricated Fishing Bumper product page.

1. Hydraulic Oil Lubrication System Ensures Long-lasting Durability in Lubricated Fishing Bumper

The internal cavity of the lubricated fishing bumper is filled with specially formulated high-viscosity hydraulic oil, creating a sealed lubrication environment. This significantly reduces friction and wear between the spring and inner walls, while the hydraulic oil’s cushioning effect minimizes peak impact forces on the tool structure. Designed to withstand high-temperature and high-pressure downhole conditions, this lubrication system ensures stable operation and extends the service life of the tool, preventing failure due to insufficient lubrication.

2. Multi-level Impact Force Adjustment Meets Complex Downhole Conditions

BESDRILL’s lubricated fishing bumper offers multiple impact force settings, including maximum unidirectional downward impact, continuous medium impact, and low-level continuous upward impact. This multi-stage design allows operators to adapt the shock force according to well conditions:

- Maximum unidirectional downward impact: Efficiently breaks severe stuck points.

- Continuous medium impact: Gradually loosens stuck pipe while protecting drill tools and wellbore integrity.

- Low-level continuous upward impact: Assists in releasing fishing tools and prevents secondary sticking.

Such flexible impact force regulation greatly enhances operational safety and success rates.

For more on impact force technologies, explore our Drilling Safety Joint product page.

3. Simple Modular Structure for Easy Maintenance and High Field Efficiency

The lubricated fishing bumper features a modular design where critical components such as springs, seals, and hydraulic chambers can be quickly disassembled and replaced onsite. Its compact structure with fewer failure points and efficient sealing systems prevents abrasive drilling fluids from entering the internal cavity, reducing wear. This streamlined maintenance process minimizes unplanned downtime and boosts drilling operation continuity and cost-effectiveness.

4. Broad Compatibility with Deep and Intermediate Well Operations

Supporting a wide range of connection sizes (API REG, NC standards), the lubricated fishing bumper is compatible with mainstream drill pipes and fishing tools, covering sizes from 2 3/8″ up to 6 5/8″. Its versatile design suits diverse drilling environments in oil & gas, geothermal, and mining industries, ensuring stable and efficient operations under various well conditions.

5. Constant Pressure Drilling Tool Functionality Enhances Downhole Stability

Besides fishing applications, the lubricated fishing bumper can function as a constant pressure drilling tool, providing consistent impact force output downhole. The hydraulic cushioning system effectively suppresses peak shock loads, reducing fatigue damage to drill tools and preventing wellbore collapse. This extends drill bit and drill pipe service life while stabilizing drilling pressure, minimizing downhole instability and ensuring smooth overall drilling operations.

For detailed technical standards, refer to the authoritative API RP 54 safety operation guidelines.

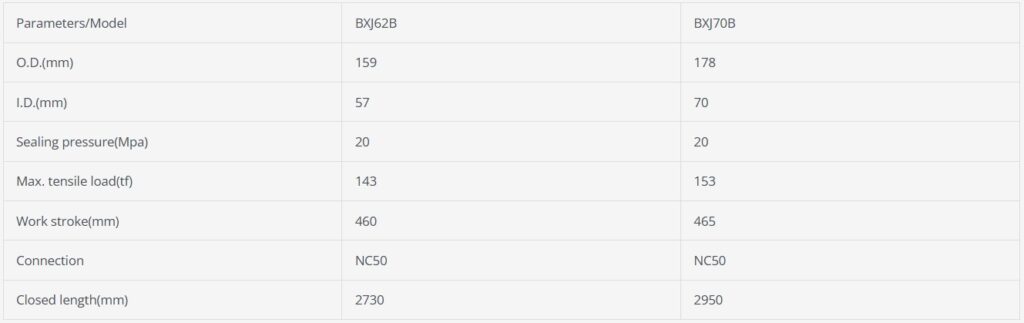

Detailed Parameters of Lubricated Fishing Bumper Models

Scientific Working Principle of the Lubricated Fishing Bumper

The impact force generation in the lubricated fishing bumper is based on energy conversion stored in the drill pipe and spring:

- Potential Energy Storage: As the drill pipe lifts, the bumper barrel is pulled downward to a preset height, accumulating potential energy.

- Spring Strain Energy: Continued lifting elongates the internal spring, storing elastic energy.

- Energy Release: When the drill pipe suddenly drops, the stored energy in the spring and pipe converts into kinetic energy.

- Impact Force Generation: Upon closure of the bumper, this kinetic energy converts to a strong impact force directed at the stuck point to facilitate release.

The hydraulic oil cushioning ensures a smooth shock process, preventing secondary damage to tools and wellbore.

Key Factors Influencing Impact Force in the Lubricated Fishing Bumper

- Suspended Weight on Drill Pipe: Higher suspended weight increases stored potential energy and impact force but must remain within design limits.

- Spring Extension Length: Greater spring elongation stores more energy, enhancing shock effectiveness; optimal spring stiffness and preload are critical.

- Stroke Length of the Barrel: Longer stroke provides greater energy conversion space, increasing impact force.

- Hydraulic Oil Viscosity and Lubrication Quality: High-viscosity oil offers superior cushioning and reduces peak shocks; lower viscosity oil suits high-frequency impacts for quick responsiveness.

Typical Applications and Advantages of BESDRILL Lubricated Fishing Bumper

- Oil & Gas Drilling Stuck Pipe Release: Powerful impact quickly breaks stuck points, shortening operation time and reducing costs.

- Geothermal Drilling in High-Temperature, High-Pressure Wells: High-temperature resistant materials and hydraulic fluids ensure system reliability.

- Horizontal and Directional Drilling in Complex Formations: Multi-level impact adapts to varying geology, protecting drill string and wellbore.

- Offshore Drilling with Corrosion Resistance: Constructed with high-strength alloy steel and anti-corrosion coatings for marine environments.

- Mining and Water Well Drilling: Universal compatibility assists stuck pipe issues across multiple sectors.

Our clients have reported significant reductions in unplanned downtime and improved operational efficiency using BESDRILL fishing bumpers. Read more in our case studies.

Why Choose BESDRILL Lubricated Fishing Bumper?

BESDRILL adheres strictly to international standards such as API RP 54. Our products utilize high-strength alloy steel and advanced heat treatment processes to ensure structural integrity and durability. Multi-size connections accommodate various fishing tools and drill pipes to meet diverse downhole needs. Our dedicated after-sales team offers customized solutions to guarantee smooth field operations. For detailed standards, visit the official API RP 54 documentation.

The BESDRILL lubricated fishing bumper, with its advanced hydraulic lubrication, optimized structure, and superior materials, stands out as the ultimate tool for resolving stuck pipe issues downhole. Master these 5 core technical advantages to boost impact force output, quickly free stuck pipes, and secure safe, stable drilling operations. Contact BESDRILL now for expert customized services and technical support to ensure your drilling project’s success!