Mud pump valve spring failure is one of the most common issues that can compromise the performance and safety of a mud pump during drilling operations. As a critical component in the valve assembly, the valve spring in a Besdrill mud pump controls valve opening pressure and ensures consistent sealing. Its integrity directly impacts mud circulation efficiency and well control reliability.

When the mud pump spring fails, improper valve action can lead to pressure loss, component wear, and even serious drilling hazards such as blowouts or loss of circulation.

Understanding the causes of mud pump spring failure and implementing effective preventive measures is essential for ensuring the long-term reliability of Besdrill mud pumps.

Main Causes of Mud Pump Valve Spring Failure

1. Load Types and Stress Concentration

Mud pump valve springs are constantly subjected to a combination of static, impact, and vibration loads. Static loads stem from high-pressure conditions during pumping, while impact loads arise during pump startup, shutdown, or sudden pressure fluctuations. Vibration loads result from the cyclic nature of pump operations.

These loads cause localized high stress in the spring, particularly in bending regions or surface defects. Over time, cyclic high stress leads to fatigue cracks, ultimately causing spring breakage.

2. Hydrogen Embrittlement in Acidic Environments

Besdrill mud pumps are widely used in acid-based drilling fluids that contain high concentrations of hydrogen ions. Hydrogen embrittlement occurs when hydrogen atoms infiltrate the metal lattice, reducing ductility and toughness. This condition can lead to unexpected brittle fracture of the valve spring—even without visible deformation.

Hydrogen embrittlement is a hidden yet severe cause of mud pump valve spring failure, and combating it requires specialized material selection and surface protection methods.

3. Manufacturing Defects and Surface Imperfections

Precision is critical in the manufacturing of mud pump valve springs. Any deviation such as excessive bending, surface scratches, or tight radius corners can result in stress concentration zones, lowering fatigue resistance.

Besdrill addresses this by using CNC-controlled processes and ultra-fine polishing techniques to minimize surface flaws and dimensional errors, reducing the risk of failure due to manufacturing defects.

4. Fatigue Failure from Repeated Cycles

Even when the applied load is below the material’s yield strength, repeated stress cycles—especially in high-frequency operations—can eventually initiate and propagate fatigue cracks. Fatigue failure is the most common failure mode in mud pump springs and a primary focus of Besdrill’s engineering efforts.

Besdrill’s Preventive Measures and Technical Innovations

1. Advanced Stress Optimization Design

Besdrill uses Finite Element Analysis (FEA) to simulate stress distribution across the spring. Through variable pitch design and optimized wire diameter distribution, we reduce peak stress concentrations and extend spring service life.

2. High-Performance Alloys with Hydrogen Resistance

Besdrill mud pump springs utilize our proprietary BES-900 series high-strength spring steel, which offers excellent hydrogen embrittlement resistance and corrosion protection. Surface treatments such as nitriding and phosphating create barriers that prevent hydrogen infiltration.

3. Precision Manufacturing and Quality Control

Our CNC machining ensures accurate control of bend radii and dimensional tolerances. The spring surfaces are polished to a roughness of Ra ≤ 0.4 µm, reducing crack initiation sites. Each unit undergoes 100% magnetic particle and ultrasonic testing to eliminate hidden defects.

4. Anti-Fatigue Surface Treatment

Besdrill adopts shot peening to introduce a compressive residual stress layer (≥300 MPa) on the spring surface, which delays fatigue crack formation. Carburizing and carbonitriding further improve hardness and wear resistance.

5. Certified Quality Assurance

Our mud pump valve springs comply with API 7K and ISO 13628 standards. We perform rigorous low and high-temperature cyclic testing and fatigue life simulation, supported by a full lifecycle traceability system to ensure consistent product quality.

Why Choose Besdrill Mud Pump Valve Springs?

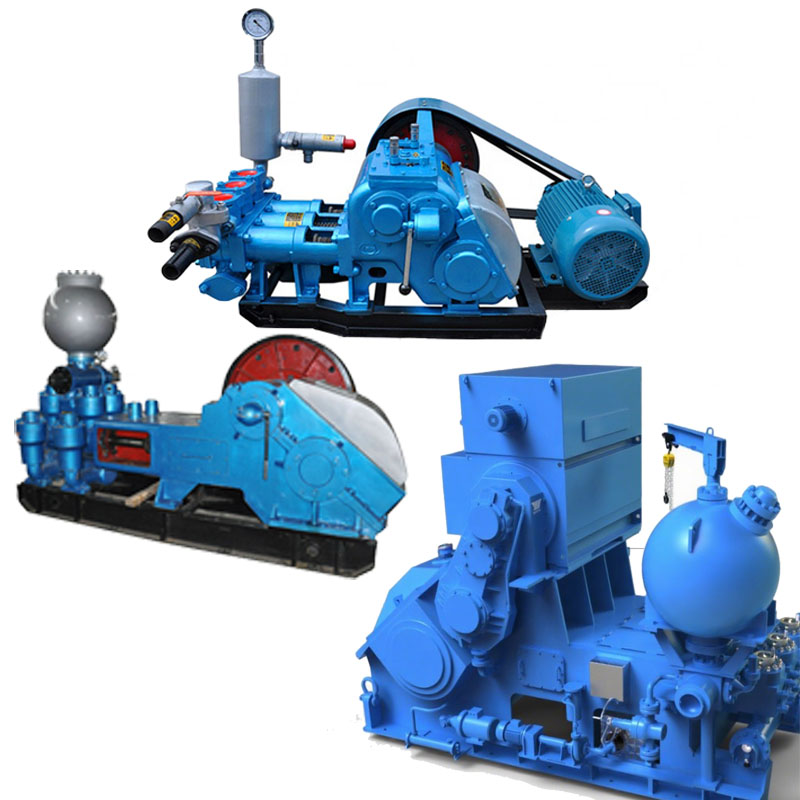

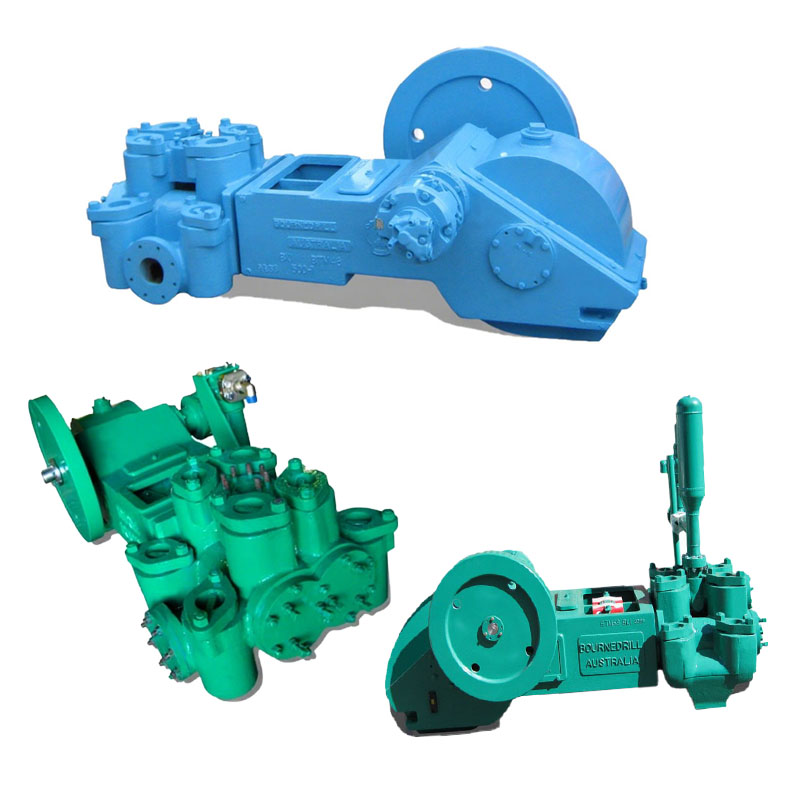

Besdrill mud pump valve springs are trusted globally for their superior material properties, robust design, and reliable performance. They are widely used in oil & gas exploration, geothermal drilling, and water well drilling applications.

Choosing Besdrill means choosing longer lifespan, lower maintenance cost, and enhanced operational safety for your drilling equipment.

Conclusion

Mud pump valve spring failure is a key factor affecting the operational integrity of any mud pump. Besdrill is committed to providing high-reliability spring solutions by addressing failure mechanisms through advanced design, material science, and strict manufacturing standards.

For more details on our mud pump products and technical support, please visit our Product Center🔗.