Our Main Products

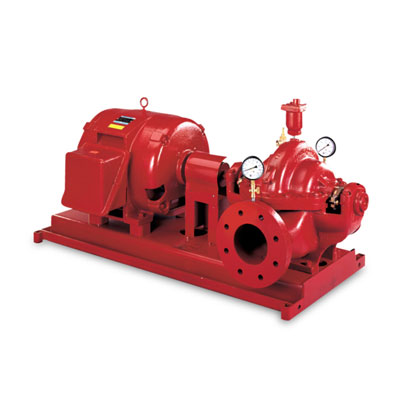

Product Argument

- Maximum input power: 121kw(165HP)

- Maximum number of strokes: 300

- Stroke: 127 mm (5 “)

- Maximum working pressure: 10000 psi

- Suction nozzle: 6 “welded pipe or 6” (150#) flange

- Discharge orifice: 2 9/16 “-10000 psi flange

- Pump weight: 1755 kg (excluding base)

Product Features:

- Input crankshaft end directly.

- The housing is an integral ductile iron.

- Alloy steel casting crankshaft.

- Convenient replacement and maintenance.

- Alloy steel forging liquid cylinder.

Recommended Products

Centrifugal pump

Water pump

Marine Pump

Pool pump

Air pump

Mud Pump

Detailed Parameter List

Marine Pumps

Max Flow: 18GPM (60LPM 50Hz)

Max Head: 29 Feet (6.3M 50Hz)

Submersible and Non Submersible

Multistage Pumps

Max Flow: 22GPM

Max Head: 87 Feet

Material: Polypropylene

1Ph 115V/230V, 3Ph 230/460V, 575V

Hydronic Pumps

Maximum flow of 29GPM

Maximum head of 30.5 feet

Material: 304SS and Brass

Flange and Threaded Connections

1Ph 115/230V

Beer Pumps

Max Flow: 120GPM (400LPM 50Hz)

Max Head: 90 Feet (19.3M 50Hz)

Material: Polysulfone and 316 Stainless Steel

Threaded and Tri Clamp Connections

Air Motor Pumps

Max Flow: 97GPM (367LPM)

Max Head: 86 Feet (26.2M)

Available in Polypropylene, Kynar, and 316 Stainless Steel

Submersible Pumps

Max Flow: 14.5GPM (54.8 LPM)

Max Head: 27 Feet (6 Meters)

12V or 24V Brushless, 115V or 230V

DC Pumps

Max Flow: 6GPM (22.7 LPM)

Max Head: 29 Feet (8.8 Meters)

Material: Polysulfone, Polypropylene, Brass, and Stainless Steel

12V, 24V, and 90V DC Brushtype and Brushlessv

Self Priming Pumps

Max Flow: 80GPM (363LPM)

Max Head: 86 Feet (26 Meters)

Max Suction Lift: 16 Feet

Materials: Polypropylene and Kynar

Pump Solutions Capabilities

Repair

>Failure analysis

>Pressure checks (excluding packed pumps)

>Detailed inspection reports

>Protective coating application

Fabrication

>Assembly

>Custom-mounted/mobile packages

>Engineered drawings

>Impeller trimming/balancing

Application

>Efficient product solutions

>Product interchange

>Systems analysis/design

>Technical troubleshooting

Product

>Centrifugal

>Positive displacement

>Process pump accessories

>Pump protection systems

Why Choose Us

Product performance excellence

The use of high-quality materials and precision manufacturing processes to ensure that the mud pump has wear resistance, corrosion resistance, long life and other excellent performance, suitable for a variety of complex conditions.

Diversified product line

Mud pumps are available in a variety of models, specifications and applications to meet the needs of different industries such as mining, drilling and construction, and support customized services.

Advanced technical support

The R & D team focuses on technological innovation, and the products have the characteristics of high efficiency and low energy consumption, combined with intelligent control technology to improve customer experience.

Quality assurance system

Strictly implement the ISO quality management system, from raw material procurement to finished products, to ensure the reliability and stability of each mud pump.

Fast delivery capability

Efficient production process and perfect inventory management system, shorten the delivery cycle, to ensure customer projects on time.

Customer customization and partnership

Listen to customer needs, provide personalized solutions, and establish long-term partnerships to achieve sustainable development.

Get a Quote Now !

You can contact us at.

Phone: +86 135 6491 6945

Email: sales@besdrill.com

Creating value for our customers is at the heart of our business. We prioritize our customers’ perspectives and goals rather than simply selling products. This customer-focused approach has helped us build many long-term partnerships and allows us to leverage over years of industry experience to deliver advanced services, including custom designs, model selection, and comprehensive pre-sales and after-sales support.