When imagining oil drilling, most people think of towering rigs, roaring engines, or the deep mysteries of what lies beneath the surface. Rarely does the spotlight fall on the equipment that makes the entire operation possible—tools like oilfield tongs. These mechanical powerhouses might not get the glamour, but without them, modern drilling would quite literally come unthreaded.

What Exactly Are Oilfield Tongs?

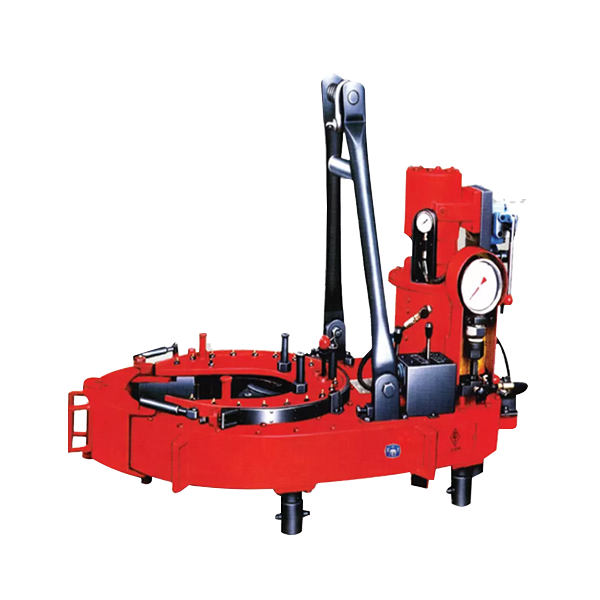

Oilfield tongs are large, clamp-like tools used to grip and rotate drill pipe, casing, or tubing during the process of making up (tightening) or breaking out (loosening) connections on a drill string. They’re essentially the oilfield version of a wrench—only super-sized, often hydraulically powered, and capable of handling torque levels measured in tens of thousands of foot-pounds.

There are two main types:

- Manual Tongs: Operated by rig workers, often used as backups or in lighter-duty situations.

- Power Tongs: Hydraulic or pneumatic tongs controlled remotely or by a driller, offering speed, consistency, and safety.

Why They Matter More Than You Think

At first glance, tongs might seem like a basic utility. But their role is fundamental. A drill pipe connection that’s too loose can fail under pressure, risking a blowout or lost tools. Too tight, and it may damage the threads or require excessive force to disassemble later. Precision torque is critical—and oilfield tongs deliver it.

Moreover, in environments where every second of rig time costs thousands of dollars, the efficiency of power tongs translates directly into saved time and money. Add to that the improved safety by reducing the need for manual handling, and their value becomes unmistakable.

Evolution Behind the Iron Grip

The earliest tongs were heavy, muscle-driven tools forged in iron—relying on brute strength and teamwork. Today, smart tongs come equipped with digital torque monitoring, automated make-up/break-out systems, and data logging, contributing to predictive maintenance and safer operations. In a sense, they’ve gone from being a hammer to becoming a precision instrument.

More Than Just a Tool

Oilfield tongs are a lesson in engineering pragmatism: build something strong enough to twist steel pipe in the harshest environments on Earth—and make it reliable enough to do it over and over, day after day. They’re not just tools; they’re part of the heartbeat of every drilling operation.

So the next time you see footage of a drilling rig silhouetted against the desert or sea, remember the quiet giants at work on the floor below. The tongs might not roar, but they turn the wheel of energy one torque at a time.