In the oil and gas industry, the efficiency and safety of drilling operations depend on countless crucial components, and one often underrated yet vital piece of equipment is the power tong. As the “torque powerhouse” for making and breaking pipe connections, power tongs not only enhance operational efficiency but also play a critical role in ensuring the safety of the crew during these high-stakes tasks.

For drilling equipment suppliers, understanding the full value, capabilities, and applications of power tongs can help customers optimize their operations and drive quality inquiries and partnerships.

1. What Are Power Tongs? – The Hydraulic “Mechanical Arm” of the Drilling Site

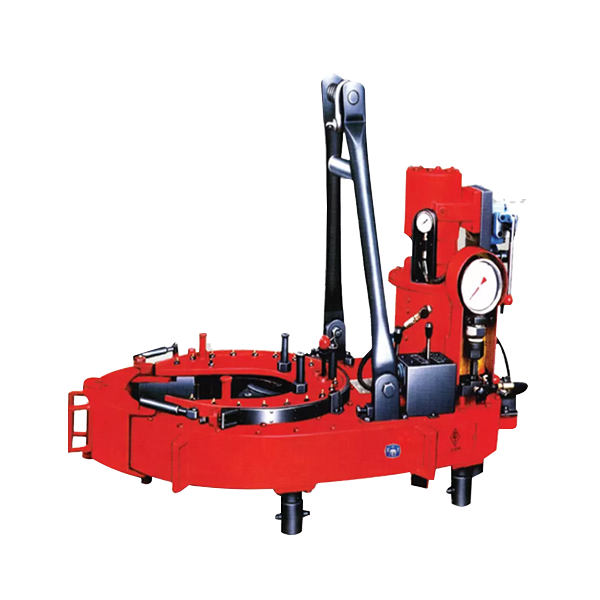

A power tong is a hydraulic or electric-driven rotary tool used for applying high torque to make or break connections between drill pipes, casing, and tubing. Traditional manual operations simply cannot meet the high-frequency, high-precision requirements of modern drilling operations. Power tongs, however, offer a solution to this problem.

By automatically applying preset torque, power tongs significantly reduce human error and fatigue while ensuring consistent, reliable connections. Whether it’s in the oil fields or offshore rigs, the ability to safely and efficiently make or break connections under pressure is critical to drilling success.

2. How Power Tongs Work – The Science Behind the Torque

Power tongs function by gripping the pipe and applying torque in a controlled manner. The tool consists of several key components:

- Torque mechanism: The motor-driven or hydraulic system that delivers the necessary torque.

- Jaws: These are the gripping components that securely hold the pipe during connection or disconnection.

- Control system: Ensures the correct application of torque, minimizing over-tightening or under-tightening.

The entire process ensures a smooth, rapid connection and disconnection of drill pipes or casing, which is essential for maintaining drilling efficiency and minimizing downtime.

3. Why Power Tongs Are a Game-Changer for Drilling Operations

In drilling operations, downtime can be extremely costly. Every minute spent manually connecting or disconnecting pipes without the aid of efficient equipment adds to non-productive time (NPT). Power tongs, by automating the torque application, allow drilling teams to:

- Increase Speed: Automated high-torque application accelerates the pipe connection process, reducing the overall operation time.

- Enhance Safety: With consistent torque control, power tongs minimize human error, reducing the risk of unsafe connections or over-tightened joints.

- Boost Efficiency: Power tongs ensure that connections are made with optimal precision, which leads to better performance during drilling and fewer incidents of pipe failure or leakage.

4. BESDRILL Power Tongs – Precision, Durability, and Performance

At BESDRILL, we understand that reliable, high-performance equipment is essential for successful drilling operations. Our range of power tongs is engineered to meet the demanding conditions of both onshore and offshore drilling environments. With high-strength materials, advanced hydraulic systems, and customizable options, our power tongs deliver the performance you need to keep your operations running smoothly.

Why choose BESDRILL power tongs?

- Durable Construction: Built with robust materials to withstand extreme environments.

- Precise Torque Control: Ensures the optimal connection every time.

- Advanced Technology: Incorporates modern automation to streamline operations.

- Expert Support: Our team is available to help you select the right equipment for your specific needs.

5. Ready to Optimize Your Drilling Operations?

If you’re looking to enhance the efficiency, safety, and speed of your drilling operations, upgrading to high-quality power tongs is a smart investment. Contact BESDRILL today to learn more about how our power tongs can improve your drilling operations and reduce downtime. Let us help you make every connection count.