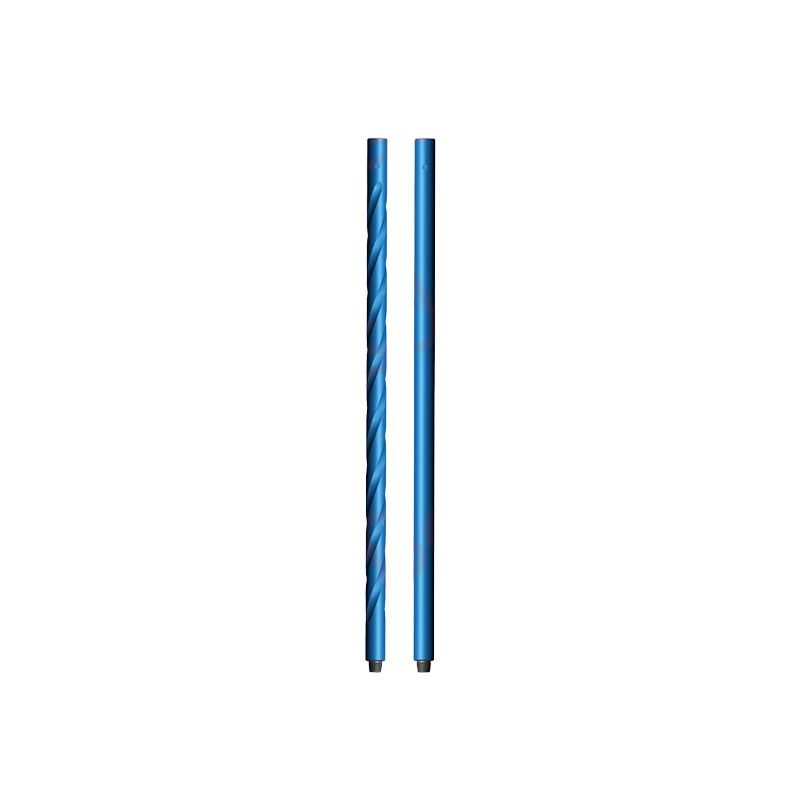

Drill Collar-Standard and Spiral

Besdrill Drill Collar has been approved by the NS-1 certification, it is manufactured from 4145H modified quenched and tempered steel, strict metallurgical specifications are followed to insure that full length heat treating produces a consistent maximum depth of hardness.

Parameter of Drill Collar-Standard and Spiral

Drill Collar is the basic component in the BHA which provides weight on the bit for drilling and keeps the drillsting in tension.

Besdrill Drill Collar has been approved by the NS-1 certification, it is manufactured from 4145H modified quenched and tempered steel, strict metallurgical specifications are followed to insure that full length heat treating produces a consistent maximum depth of hardness.

Features and Benefits

- A hardness range of 285 to 341 BHN and a Charpy impact value of 40 ft-lbs are guaranteed at evenly distributed 16 points in any sections at room temperature;

- Connections are completed(phosphate coated)to protect them from the elements after machining and to help prevent galling upon initial make-up;

- Thread roots are cold rolled on API and H-90 connections;

- Pressed steel thread protectors are supplied for all drill collar that are equipped with standard connections When ordering Please specify;

- Drill collar OD and ID;

- Overall length;

- Connections required (size and type);

- Special features desired, for example:

Slick or Spiral;

Stress Relief Features;

Slip and/or Elevator Recess;

Hard banding;

| umber and connection table | Outside Diameter | Inside Diameter | Length

mm |

Belvel Diameter

Mm |

Bending

Strength Ratio |

||

| mm | In | mm | in | ||||

| NC23-31 | 79.4 | 3 1/8 | 31.8 | 1 1/2 | 9150 | 76.2 | 2.57:1 |

| NC26-35(2 3/8 IF) | 88.9 | 3 1/2 | 38.1 | 1 1/2 | 9150 | 82.9 | 2.42:1 |

| NC31-41(2 7/8 IF) | 104.8 | 4 1/8 | 50.8 | 2 | 9150 | 100.4 | 2.43:1 |

| NC35-47 | 120.6 | 4 3/4 | 50.8 | 2 | 9150 | 114.7 | 2.58:1 |

| NC38-50(3 1/2IF) | 127 | 5 | 57.2 | 2 1/4 | 9150 | 121 | 2.38:1 |

| NC44-60 | 152.4 | 6 | 57.2 | 2 1/4 | 9150 or 9450 | 144.5 | 2.49:1 |

| NC44-60 | 152.4 | 5 | 71.4 | 2 13/16 | 9150 or 9450 | 144.5 | 2.84:1 |

| NC44-62 | 158.8 | 6 1/4 | 57.2 | 2 1/4 | 9150 or 9450 | 149.2 | 2.91:1 |

| NC44-62(4IF) | 158.8 | 6 1/2 | 71.4 | 2 13/16 | 9150 or 9450 | 150 | 2.63:1 |

| NC44-65(4IF) | 165.1 | 6 1/2 | 57.2 | 2 1/4 | 9150 or 9450 | 154.8 | 2.76:1 |

| NC44-65(4IF) | 165.1 | 6 1/2 | 71.4 | 2 13/16 | 9150 or 9450 | 154.8 | 3.05:1 |

| NC44-67(4IF) | 171.4 | 6 3/4 | 57.2 | 2 1/4 | 9150 or 9450 | 159.5 | 3.18:1 |

| NC50-672(4 1/2IF) | 171.4 | 6 3/4 | 71.4 | 2 13/16 | 9150 or 9450 | 159.5 | 2.37:1 |

| NC50-70(4 1/2IF) | 177.8 | 7 | 57.2 | 2 1/4 | 9150 or 9450 | 164.7 | 2.54:1 |

| NC50-70(4 1/2IF) | 177.8 | 7 | 71.4 | 2 13/16 | 9150 or 9450 | 164.7 | 2.73:1 |

| NC50-72(4 1/2IF) | 184.2 | 7 1/4 | 71.4 | 2 13/16 | 9150 or 9450 | 169.5 | 3.21:1 |

| NC56-77 | 196.8 | 7 3/4 | 71.4 | 2 13/16 | 9150 or 9450 | 185.3 | 2.70:1 |

| NC56-80 | 203.2 | 8 | 71.4 | 2 13/16 | 9150 or 9450 | 190.1 | 3.02:1 |

| 6 5/8REG | 209.6 | 8 1/4 | 71.4 | 2 13/16 | 9150 or 9450 | 195.7 | 2.93:1 |

| NC61-90 | 228.6 | 9 | 71.4 | 2 13/16 | 9150 or 9450 | 212.7 | 3.17:1 |

| 7 5/8 REG | 241.3 | 9 1/2 | 76.2 | 3 | 9150 or 9450 | 223.8 | 2.81:1 |

| NC70-97 | 247.6 | 9 3/4 | 76.2 | 3 | 9150 or 9450 | 232.6 | 2.57:1 |

| NC70-100 | 254 | 10 | 76.2 | 3 | 9150 or 9450 | 237.3 | 2.81:1 |

| 8 5/8 REG | 279.4 | 11 | 76.2 | 3 | 9150 or 9450 | 266.7 | 2.84:1 |

| Slips and elevator grooves can be produced upon the customers’ requirement. | |||||||

Want to Know More Detail About This Drilling Equipment?

相关产品

-

Drill Pipe

DRILL PIPE

-

Drill Pipe

Tool Joints

-

Drill Collar

Non-Magnetic Drill Collar

-

Drill Pipe

Oil Drill Pipe