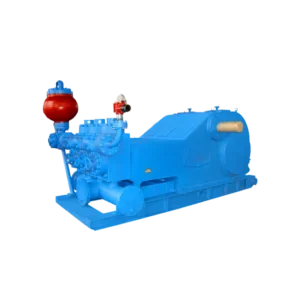

F Series F1300 Mud Pump

Wheel set of transmission gear It is in integrated herringbone gear transmission, the drive torque is high and the operation is smooth.

Parameter of F Series F1300 Mud Pump

Wheel set of transmission gear It is in integrated herringbone gear transmission, the drive torque is high and the operation is smooth.

Frame It is in structure of steel plate welding, the main bearing base and upper and lower seats for crank shaft adopt cast steel, and they have the stress relieving treatment after welding. The lower seat of crank shaft adopts the stiffened reinforcing structure, the rigidity is good and strength is high. The necessary system of oil sump and oil channel have been matched on

the frame for the cooling and lubrication.

Crank shaft It is casted by alloy steel. The large gear ring is the integrated herringbone gear, the inner hole and crank shaft is in tight fit, and are fastened by bolts and blocking nuts.

Pinion It is the forged by alloy steel. The herringbone teeth are machined on the shaft. It adopts the medium hard tooth flank.

Crosshead It adopts ductile iron cast and has the good antifriction performance. The guide plate adopts the structure of upper and lower guide plates, which can adjust concentricity through adding washer at the lower guide plate.

Hydraulic cylinder It is the forged by alloy steel. It is in the form of straight-way type cylinder. There are saw tooth threads on the top. The surface of hydraulic cylinder can be treated by chemical nickel and phosphorus plating to enhance the performance of anti-corrosion.

Valve assembly F-800 and F-1000 mud pumps adopt API 7# valve. The parts of hydraulic cylinder, cylinder, plunger, valve, valve seat, valve spring, sealing part, valve cap and cylinder cap, etc. at the fluid end of F-800 and F-1000 mud pumps can be interchanged.

The parts at fluid end of F-1300 and F-1600 mud pumps can be interchangeable.

Lubrication system It adopts the method of forced lubrication and splash lubrication.

| Cylinder diameter | in | 7 | 6 3/4 | 6 1/2 | 6 1/4 | 6 | 5 1/2 | 5 | |

| Discharge pressure | Mpa | 18.9 | 20.4 | 22.0 | 23.8 | 25.8 | 30.7 | 34.5 | |

| psi | 2720 | 3050 | 3188 | 3440 | 3915 | 4495 | 5000 | ||

| Stroke | Input power | Discharge capacity (L/s) | |||||||

| min-1 | KW | Horsepower | |||||||

| 120 | 956 | 1300 | 45.41 | 42.22 | 39.15 | 36.20 | 33.36 | 28.03 | 23.17 |

| 110 | 874 | 1188 | 41.63 | 38.7 | 35.89 | 33.18 | 30.58 | 25.69 | 21.24 |

| 100 | 795 | 1081 | 37.84 | 35.18 | 32.63 | 30.17 | 27.8 | 23.36 | 19.31 |

| 90 | 715 | 972 | 34.06 | 31.67 | 29.36 | 27.15 | 25.02 | 21.02 | 13.38 |

| 50 | 397 | 540 | 18.92 | 17.59 | 16.31 | 15.08 | 13.9 | 11.68 | 9.65 |

| 1 | 79 | 107 | 0.3784 | 0.3517 | 0.3263 | 0.3017 | 0.278 | 0.2336 | 0.1931 |

Want to Know More Detail About This Drilling Equipment?

相关产品

-

Mud Pump

F Series F1600 Mud Pump

-

Mud Pump

F Series F1000 Mud Pump

-

Mud Pump

3NB1600 Mud Pump

-

Mud Pump

3NB1300 Mud Pump