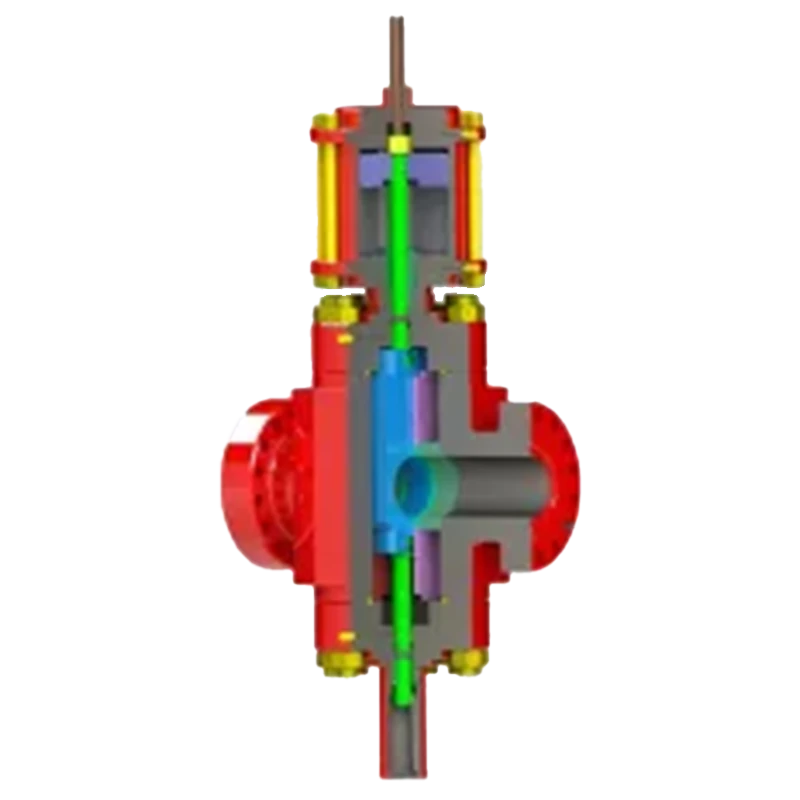

Hydraulic Gate Valves

API 6A Expanding Gate Valves are crucial components in the oil and gas industry, particularly in upstream operations such as wellheads and production facilities. These valves are designed to provide reliable and tight shut-off in high-pressure and high-temperature environments.

Parameter of Hydraulic Gate Valves

API 6A Expanding Gate Valves are crucial components in the oil and gas industry, particularly in upstream operations such as wellheads and production facilities. These valves are designed to provide reliable and tight shut-off in high-pressure and high-temperature environments.

Besdrill Machinery provides hydraulic gate valves ranging in size from 1 13/16” to 7 1/16” and pressure ratings from 2,000psi to 15,000psi. Hydraulic Gate Valve is designed and manufactured in strict accordance with API 6A. Forged or cast AISI 4130/4140 low alloy steel or AISI 410 SS steel, the actuator is designed to be safe and suitable for all kinds of Hydraulic Gate Valves.

Features

1. Forged or cast body and valve cover

2. Metal-to-metal seal, gate to valve seat, valve seat to valve body, bonnet seal and stem back seat

3. Two-way sealing

4. All internal parts can be replaced online

5. Easy to maintain and disassemble

6. Optional over-voltage protection, composite spring design, improve stability

Hydraulic Gate Valves

Operating temperature

Hydraulic Gate Valves can provide API 6A temperature class L (-50 F) to Y (650 F). According to the requirements of Appendix G of the latest version of API 6A, the pressure of valves used for API temperature classes X and Y is reduced.

Expand the door

Hydraulic Gate Valves can be replaced on site and provide tight mechanical seals that do not rely on pipeline pressure. This ensures the integrity of the seal under high pressure and low pressure.

Seat design

The standard valve seat gate and the sealing interface of the valve seat and the body adopt a sliding fit design, assisted by plug-ins on the front and back of each valve seat. Metal-to-metal gate-to-seat and press-fit valve seat-to-body seals are used for high temperature valves, otherwise it can be provided on request.

Package Design

Chevron-style stem packing is replaceable and can be re-energized by filling between packing stacks. This ensures effective sealing during the life of the valve. Graphite fillers are used for high temperature applications.

Body lubricant

All Hydraulic Gate Valves are supplied with valve body filling grease suitable for the valve material grade and temperature rating to ensure smooth operation of the valve under pressure and prevent corrosion during storage before deployment.

Grease accessories

The valve body can be lubricated by a grease nipple provided in the valve body. All accessories meet the requirements of NACE MR0175.

Exposed bolt

All exposed bolts meet the requirements of NACE MR0175.

Full-through pipe hole

The full-through duct hole provides smooth flow and minimal turbulence. It also provides unimpeded access for workover tools.

| Dimension | Size | ||||||||

| 1 13/16 | 2 1/16 | 2 9/16 | 3 1/16 | 3 1/8 | 4 1/16 | 5 1/8 | 7 1/16 | ||

| A | 5M | – | 371.5 | 422 | – | 473 | 549 | – | – |

| 10M | 164 | 521 | 565 | 619 | – | 670 | 737 | 889 | |

| 15M | 457 | 483 | 533 | 598 | – | 737 | 889 | – | |

| B | 5M | – | 215 | 245 | – | – | 310 | – | – |

| 10M | 185 | 200 | 230 | 2740 | 265 | 315 | 388 | 315 | |

| 15M | 210 | 220 | 255 | 290 | – | 360 | 310 | 476 | |

| C | 5M | – | 358.8 | 405 | – | – | 505 | – | – |

| 10M | 361 | 361 | 416 | 460 | 425 | 512 | 600 | 814 | |

| 15M | 361 | 368 | 939 | 523 | 438 | – | 615 | 830 | |

| D | 5M | – | 939 | 942 | – | – | 1196 | – | – |

| 10M | – | 942 | 1080 | 1090 | 1060 | 1278 | 1320 | 1540 | |

| 15M | – | 942 | 356 | 1250 | – | – | 1320 | 1540 | |

| E | 5M | – | 356 | 480 | – | – | 470 | – | – |

| 10M | 356 | 470 | 470 | 609.6 | 470 | 609.6 | 622 | 840 | |

| 15M | 470 | 470 | 470 | 609.6 | – | 609.6 | 622 | 870 | |

| Ring Number | 5M | – | R24 | R27 | – | – | R39 | – | – |

| 10M | BX151 | BX151 | BX153 | BX154 | R35 | BX155 | BX169 | BX156 | |

| 15M | BX151 | BX152 | BX153 | BX154 | – | BX155 | BX169 | BX156 | |

Want to Know More Detail About This Drilling Equipment?

相关产品

-

Well Head

Expanding Gate Valves

-

Well Head

Weldneck Flange

-

Well Head

Double Studded Adaptor

-

Fishing Tools

Float Valve SUB