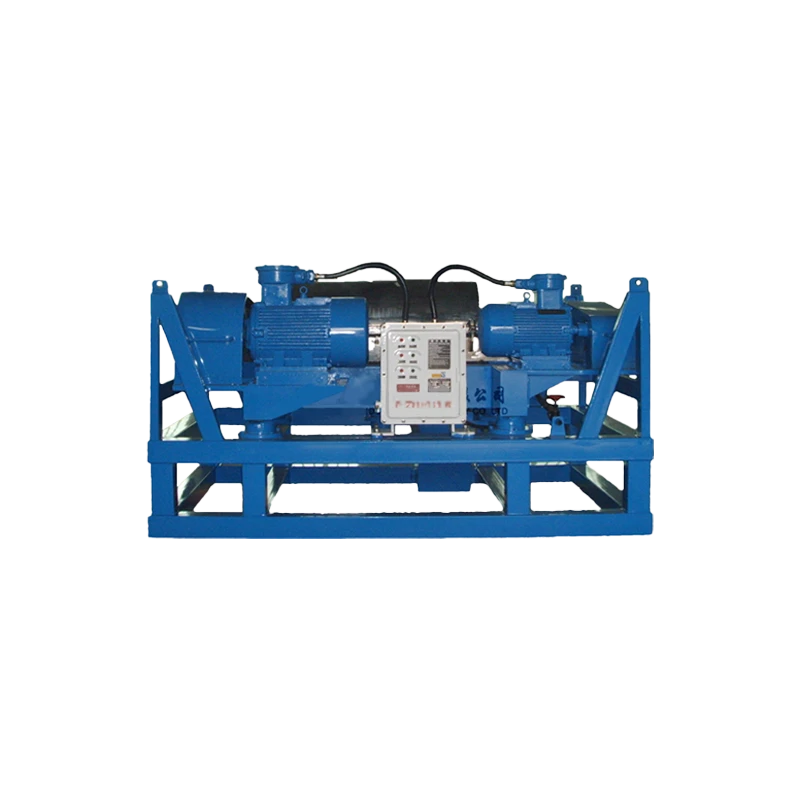

LW Series Centrifuge

The centrifuge has advantages in wide adaptability great throughput,continuous and simple operation,easy installation, and small floor area, and is mainly used in petroleum,environmental protection industry,chemical, food, paper-making, brewing and amylum,industry etc.

Parameter of LW Series Centrifuge

Usage & Application Range

The centrifuge has advantages in wide adaptability great throughput,continuous and simple operation,easy installation, and small floor area, and is mainly used in petroleum,environmental protection industry,chemical, food, paper-making, brewing and amylum,industry etc.

The decanter separates suspension based on the pinciple of centrifugal settlement.A suspension is supplied to the rotating bowl through an accelerator centrifugal force and transported towards the right shaft of the bowl by the conveyor and then discharged through solids discharge ports.While lighter liquid phase flows to liquid discharge ports at the left shaft of the bowl.

Structural Features

The centrifug is used to separate solid and liquid in the rotary drum completely.It is mainly composed of rotary drum, screw conveyor, adifferential case and motors.

The rotary assembly is mounted on the two main bearing housings horizontally.The screw conveyor is installed in the rotary drum with deep groove ball bearing and tapered roller bearing. The main motor is connected with the fluid coupling by bell wheel. The differential casa is mounted on the left shaft of the bowl and is connected to the screw conveyor with mating splines. The main motor drives the fluid coupling and then drives the screw conveyor while the secondary motor drives the differential case.

Main Technical Parmeter

| Model | GLW355×1280-N | GLW450×1260-N | LW500×1000-N | GLW500×1250-N |

| Diametet of Revolving Drum

(mm) |

355 | 450 | 500 | 500 |

| Length of Revolving Drum

(mm) |

1280 | 1260 | 1000 | 1250 |

| Rate of Length

versus Diameter (i) |

3.6 | 2.8 | 2 | 2.5 |

| Maximum speed

(r/min) |

2500~3200 | 2400~3000 | 1600~1800 | 2400~2800 |

| Separation Factor

(Fr) |

2035 | 2266 | 1100 | 2195 |

| Capacity

(m3/h) |

10~20 | 30-40 | 40~60 | 35~50 |

| Min separating point

(μm) |

2 | 2 | 5 | 3 |

| Motor power

(kW) |

22+7.5 | 37+7.5 | 30+7.5 | 37+11 |

| Weight

(kg) |

2200 | 3000 | 2800 | 3500 |

| Overall dimensions

(mm) |

3100×1470×1070 | 3100×1500×1070 | 2750×1580×1400 | 3060×1670×1400 |

| Type | Explosion-proof

high-speed dual-frequency |

Explosion-proof

high-speed dual-frequency |

Medium Speed | Explosion-proof

high-speed dual-frequency |

Want to Know More Detail About This Drilling Equipment?

相关产品

-

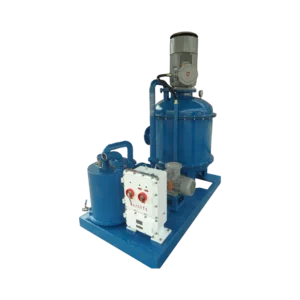

Vacuum Degasser

JZCQ-1/4(240) Vacuum Degasser

-

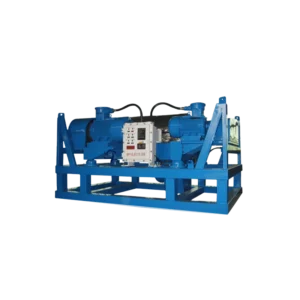

Centrifuge

LW Centrifuger

-

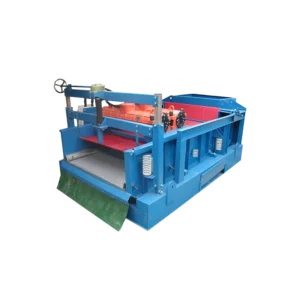

Shale Shaker

JZS280-3P Shale Shaker

-

Shale Shaker

JZS220-3P Shale Shaker