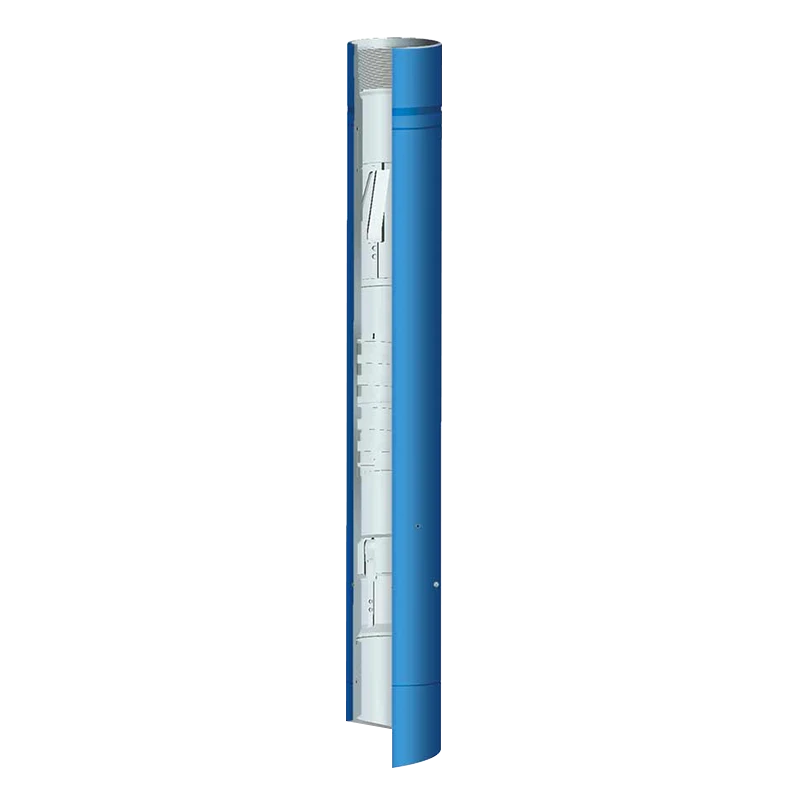

Mechanical External Cutter

After the tool connected with the wash over pipe under to the predetermined cutting position, lift the cutter, the spring dog inside the cutter on the preload sleeve withstands the shoulder of fish sub.

Parameter of Mechanical External Cutter

Work Principle

After the tool connected with the wash over pipe under to the predetermined cutting position, lift the cutter, the spring dog inside the cutter on the preload sleeve withstands the shoulder of fish sub.

If we continue to lift, the body through shear pins impels feed ring together upward movement, the spring stress compression, When the lift force over shear pins load, shear pins cut off .The spring impels the feed link downward movement: and it could let the knives rotary to the cutter center. Rotary tool, the spring impels the feed ring gradually downward to feed knives with the function the spring elastic potential energy, until the fish cut off, after cut off the fish, the preload sleeve card tight wrap catches the fish which cuts off to extract together.

When ordering please specify

- Hole size;

- Pipe O.D to be cut;

- Top connection.

Specifications – Mechanical External Cutter

| Model | WD-J145 |

| O.D. (mm) | 154 |

| I.D. mm) | 124 |

| Pipe Size of Cutting | 63.0-101.6 tubing |

| Min.Hole Size (mm) | 159 |

| Max.Fishing Size (mm) | 121 |

| Double Shear Strength (kg) | 579 |

| connection | 5 1/2” LCSG |

Want to Know More Detail About This Drilling Equipment?

相关产品

-

Fishing Tools

Series 70 Shot Catch Overshot

-

Fishing Tools

Impression Blocks

-

Fishing Tools

H Type Safety Joint

-

Fishing Tools

Cable Fishhook