NON-KILL BOP

An essential piece of machinery in the oil and gas sector is the blow out preventer (BOP) system, which is made up of a number of components, including a Ram Blowout Preventer.

Parameter of NON-KILL BOP

An essential piece of machinery in the oil and gas sector is the blow out preventer (BOP) system, which is made up of a number of components, including a Ram Blowout Preventer, an Annular Blowout Preventer. a Pulsation dampener, Valves, Soare pants. and a Choke & Kill Manifold, all of which work together to ensure the safety and control of high-pressure wells.

Non-kill operation means the type of operation in which operation is made without open flow and well kill when there is pressure inside well. DYZY18 -14 /21 and DYZY18-21/35 non-kill BOP is a set of device for non-kill operation, and its main function is to control pressure of well head during operation, effectively prevent the accident of blowout, and realize the safe operation.

| Item | Technical Parameter | |

| DYZY18-14/21 | DYZY18-21/35 | |

| Stroke length of rising and falling cylinder | 3.5m | |

| Pushingupforceofrisingandfallingcylinder(Maximum) | 500KN | 600KN |

| Pulling down force of rising and falling cylinder (Maximum) | 350KN | 420KN |

| Maximum working pressure | 14Mpa | 21Mpa |

| Maximum bearing pressure | 21Mpa | 35Mpa |

| Strength testing pressure for pressure containing parts | 42Mpa | 70Mpa |

| Bore size | φ186mm | |

| Size of ram equipped for ram BOP | Full sealing、2 7/8"、1 1/2" | |

| Recommended control pressure for ram BOP | 8.4-10.5MPa | |

| Size of slip element for slips | 2 7/8"、1 1/2" | |

| Dimension (L×W×H) mm | 1780X1400X5720 | |

| Temperature grade for metal pressurecontaining parts | T20(-29~121℃) | |

| Temperature gradeforcommonnon-metal sealing parts | BB(-18~93℃) | |

| Temperature grade of cold-resistant non-metal sealing parts | AB(-26~93℃) | |

| Working media | Water, crude oil, drilling liquid (Not suitable to the

environmental with sulfureted hydrogen) |

|

Want to Know More Detail About This Drilling Equipment?

Related products

-

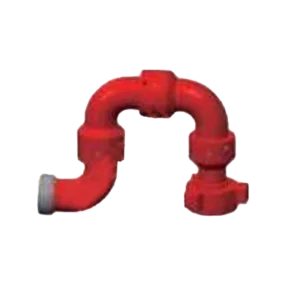

Swing Joint

Long Radius Swivel Joints-Style 80 F x M

-

Swing Joint

Long Radius Swivel Joints-Style 30 F x M

-

Swing Joint

High Pressure Swivel Joints