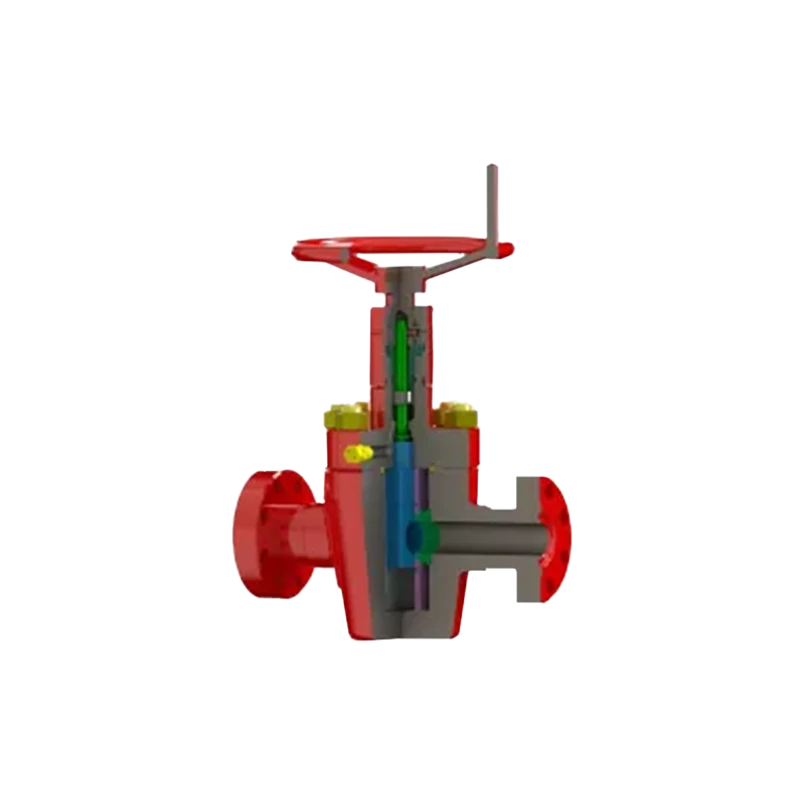

Slab Gate Valve

Besdrill Machinery’s high-performance two-way flat API 6A Slab Gate Valve is designed for critical high-pressure applications, ranging from 3000 psi to 15000 psi. It is ideal for use in wellheads, Christmas trees, and manifolds.

Parameter of Slab Gate Valve

Besdrill Machinery’s high-performance two-way flat API 6A Slab Gate Valve is designed for critical high-pressure applications, ranging from 3000 psi to 15000 psi. It is ideal for use in wellheads, Christmas trees, and manifolds.

Types

API 6A Slab Gate Valve have PFFA Series and PFF series. Details as below:

PFFA Series Gate valve

Full bore design eliminates efficiently pressure drop and vortex, eliminates washing by solids in fluid.

Mental-to-mental seal is used between bonnet and body, gate and seat body and seat

The surface of gate andseat is weld overlay with hard alloy. which has feature of corrosion resistance and washing resistance.

The bonnet and stem designed with back seal, can replace stem sealing under pressure

One side of bonnet is designed with sealant injection in order to supply sealant and improve seal and lubrication performance of gate and seat.

Can complete with different pneumatic (hydraulic) actuator upon user s requirements

Working Pressure: 2000PSI-20000PSI

Nominal Bore: 1-13/16-9″(46mm-230mm)

Working Medium: oil、 natural gas、 mud and gas ,containing has、co

Working Temperature:-46C-121’C(Class LU)

Material Class: AA、BB、cc、DD、EE、FF、HH

Specification level: PSL1-4

Performance Requirement: PR1-2

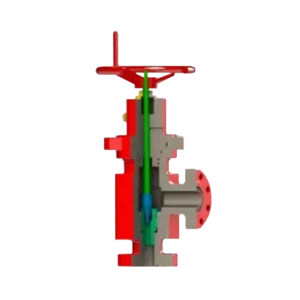

PFF Series Gate Valve

Full bore design eliminates efficiently pressure drop and vortex eliminates washing by solids in fluid

Mental-to-mental seal is used between bonnet and body, gate and seat, seat and body

The surface of gate and seat is welding overlay with hard alloy, which has feature of

corrosion resistance and washing resistance.

The balanced stem can balance the stem load. Reduce load of stem thread and bearing to decrease operating torque.

The bonnet and stem are designed with back seal, which can replace stem sealing under pressure.

One side of bonnet is designed with sealant injection valve.

Rising stem structure can indicate open and close of valve.

Complete with different pneumatic(hydraulic) actuator upon users requirements.

Working Pressure: 2000PSI–20000PSI

Nominal Bore: 1.13/16-9″(46mm-230mm

Working Medium: oil、 natural gas、 mud and gas, containing H:S、co

Working Temperature: -46C-121C(Class

Material Class: AA、BB、cc、DD、EE、FF、

Specification level: PSL1–4

Performance Requirement: PR1-2

Design Features

Full port design

Double blocking and discharge

Emergency sealant injection

Single or double reel

Orifice type or non-orifice

Flange or butt welding end

Fire protection design conforms to API 6A

Want to Know More Detail About This Drilling Equipment?

相关产品

-

Well Head

Low-Alloy Steel Choke Valve

-

Well Head

Casing Spool

-

Fishing Tools

Float Valve SUB

-

Fishing Tools

By-Pass Valve