Wear SUB

During drilling Operation, serious wear often takes place between drill pipes and casings. Wear Sub is used to avoid the wear between drill pipes, tool joints and casings.

Parameter of Wear SUB

During drilling Operation, serious wear often takes place between drill pipes and casings. Wear Sub is used to avoid the wear between drill pipes, tool joints and casings.

With features such as compact structure, easy operating wear sub can prolong the service life of drill pipe and casing, reduce the vibration and trembling of drilling tools, limit the contact friction between metals to metals.

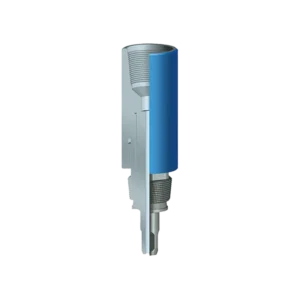

Saver subs consist of a highly wear rubber sleeve, a metal stiffening liner and a sub body. The rubber sleeve is installed in the middle of sub body and some clearance is given to allow sleeve to rotate freely. The rubber sleeves are made of rubber mixtures with good wear resistance.

During drilling operation, the rubber sleeve and sub body can make a relative rotation, rubber sleeve O.D. is larger than drill pipe tool joint O.D, so the tool joint and drill pipes can not contact with casing. The rubber sleeve on saver sub will firstly contact with casing. When friction between rubber sleeve features such as wear and soft, at the same time, consumption to tool joints of drill pipes and drill string tools will be decreased.

When ordering please specify:

- Casing size and weight, or O.D. of wear sub;

- Connection.

| Specification | Body O.D.(mm) | SubO.D.(mm) | I.D.(mm) | Connection |

| 7” Casing | 121 | 143 | 38 | 3 1/2 IF |

| 9 5/8 Casing | 168 | 190 | 57 | 4 1/2 IF |

| 178 | 197 | 71 | 5 1/2 FH | |

| 10 3/4” Casing | 180 | 225 | 71 | 4 1/2 FH |

| 5 1/2 FH | ||||

| 13 3/8 Casing | 228 | 285 | 71 | 5 1/2 FH |

Want to Know More Detail About This Drilling Equipment?

相关产品

-

Fishing Tools

Series 10 Overshot

-

Fishing Tools

Sliding Block Spear

-

Fishing Tools

Series 70 Shot Catch Overshot

-

Fishing Tools

Reversing sub