Besdrill Oil Drilling Equipment

Your Trusted Partner for Efficient

Reliable Drilling Solutions

Explore Our Oil Drilling Equipment Solutions

Production Equipment

.

Drill Bits and Drilling Tools

Mud Circulation System

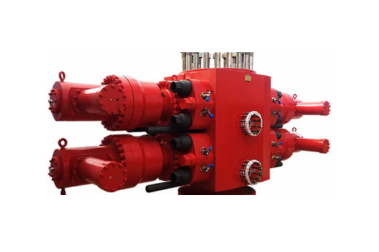

Blowout Preventer, BOP

Downhole Tools

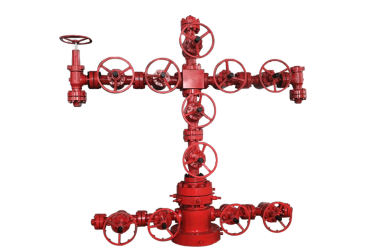

Wellhead Equipment

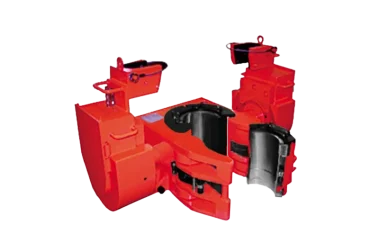

Elevators

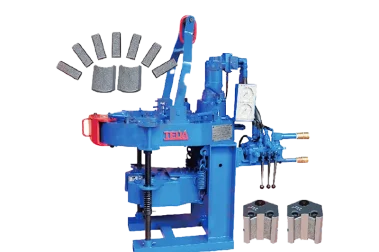

Power Tongs

Drill Pipes

Why Choose Us?

Cutting-Edge Drilling Technology

We use the latest technology to enhance drilling efficiency and reduce costs.

Durable and Reliable Equipment

Our equipment is built for long-lasting performance in harsh environments.

Tailored Drilling Solutions

Custom-engineered equipment designed specifically to address your unique drilling challenges and optimize productivity.

24/7 Expert Support

Our experienced technical team provides round-the-clock support and maintenance to keep your operations running smoothly.

Global Delivery, Fast Turnaround

A robust supply chain ensures quick delivery worldwide.

Eco-Friendly and Safe Design

Our equipment is engineered to meet environmental standards and promote operational safety, protecting both the environment and workers.

What Our Clients Say

Besdrill's drilling equipment has been outstanding in our oil exploration projects. The reliability and operational efficiency of the rigs exceeded our expectations. The team’s support is also very responsive, ensuring our projects run smoothly.

We’ve been using Besdrill's drilling equipment for years, and it has proven to be perfect for the challenging conditions of oil drilling. The high performance and durability of the rigs have significantly boosted our drilling efficiency, saving both time and costs.

As a long-time client in the oil drilling industry, Besdrill has always been our trusted partner. Whether it’s purchasing new equipment or routine maintenance, their service is professional, ensuring that our drilling operations stay efficient and safe.