Efficient Water Well Drilling Rigs for Sale

Water well drilling rigs for all needs – from portable to deep well solutions, built for any terrain.

Explore Our Product Range

Crawler-mounted

Water Well Drilling Rig

Trailer-mounted Water Well Drilling Rig

portable

Water Well Drilling Rig

Truck-mounted

Water Well Drilling Rig

What Can We Offer

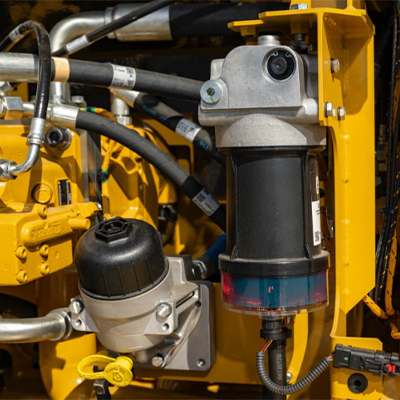

Hydraulic System

Augers & Bits

Trailer

Optional Components

Drill Rods & Drill Pipes

Mud Pumps & Parts

Drag Bits and Reamer-Stabilisers

Winches & Lifting Equipment

Application Industry

Water and geothermal drilling

Geotechnical and environmental drilling

Mineral exploration

Geothermal well

Why Choose Us

Proven Quality

Our drilling rigs are built with high-grade materials and strict quality control standards. Each machine is tested before shipment to ensure reliability, durability, and performance in demanding conditions.

Custom Solutions

From portable rigs to full-scale truck-mounted systems, we tailor equipment to your project needs, terrain type, and drilling depth. Hydraulic systems, optional components, and configuration flexibility available.

Fast & Reliable Delivery

With strong logistics capabilities, we deliver globally – fast, safe, and on time. Our rigs are packaged securely in containers or skids, ready for immediate use on arrival.

Lifetime Support

We provide full after-sales support, including spare parts, user manuals, online technical assistance, and upgrade services. Our team is always ready to help, from pre-sales consultation to long-term service.

Frequently Asked Questions

Professional service, including maintenance and water testing, should be done annually. This ensures cleanliness and efficiency, especially for wells drilled for drinking water.

With regular service, a well system can last several decades. However, its longevity depends on other factors, such as the quality of pump installation and the cleanliness of the well’s water.

Replacement costs vary, influenced by factors such as the pump repair’s complexity and the well casing’s condition. Professional drilling services are crucial for avoiding collapse and maintaining a clean water supply.

Signs of a problem include fluctuating water pressure, dirty water, and unusual noises from the pump. A drilling company can promptly repair these issues to prevent more significant problems.

Well drilling provides a reliable and clean water source independent from the public water supply. It’s cost-effective and gives homeowners control over their water quality.

Client Testimonials

Contact Us Today for a Free Quote

- Phone: +86 135-6491-6945