In the world of oil and gas drilling, precision and efficiency are paramount. Among the tools that ensure smooth operations, drill collars play an indispensable role. But what exactly are drill collars, and why are they so critical to drilling success? Let’s delve into their functions and highlight the features that make them stand out in demanding environments.

Drill Collars Function

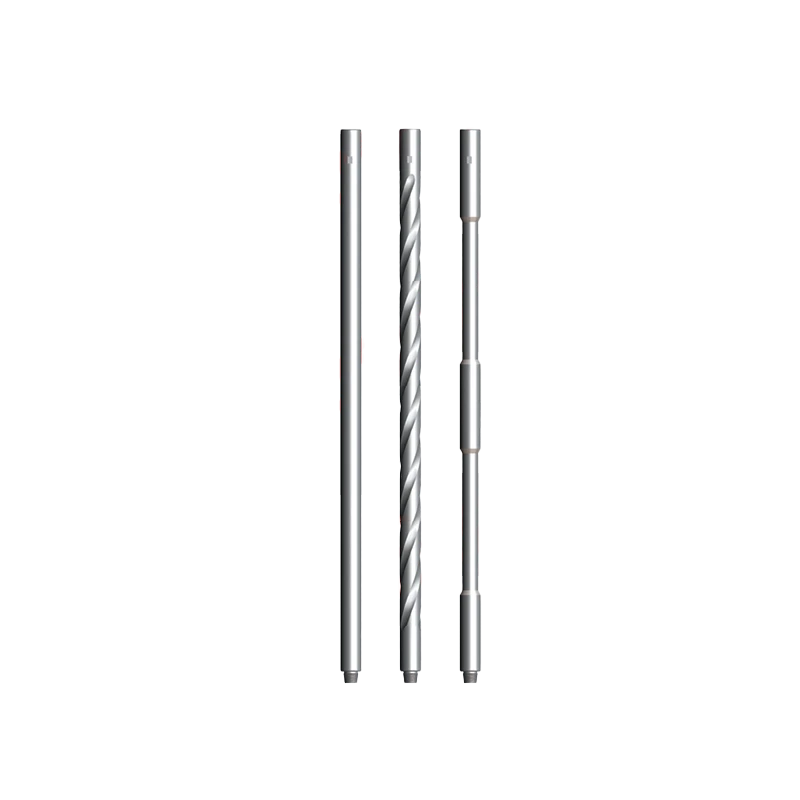

Drill collars are heavy, thick-walled tubular components used in the bottom hole assembly (BHA) of a drill string. Their primary purpose is to provide the weight needed to push the drill bit into the formation effectively. Unlike other sections of the drill string, which focus on flexibility, drill collars are designed to be robust and rigid.

Drill Collars Uses

Weight on Bit (WOB): By adding weight to the drill bit, drill collars help maintain consistent penetration rates, even in challenging formations.

Directional Control: Their stiffness minimizes bending, ensuring a straighter wellbore, which is critical for both vertical and directional drilling.

Vibration Dampening: Drill collars reduce unwanted vibrations, enhancing tool longevity and improving drilling efficiency.

Product Features That Make a Difference

When it comes to choosing the right drill collars, specific characteristics can significantly impact performance. Here are the standout features to consider:

High-Quality Material Construction

Our drill collars are manufactured using premium-grade alloy steel, ensuring exceptional strength and durability. This reduces the risk of tool failure in high-pressure and high-temperature environments.

Precise Dimensional Tolerances

With advanced machining and strict quality control, our drill collars deliver unmatched precision. This ensures seamless integration into the drill string and optimal performance throughout the drilling operation.

Advanced Threading and Connections

Reliable threading is crucial to minimize wear and ensure secure connections. Our collars feature industry-standard threads with customizable options, tailored to your operational needs.

Non-Magnetic Options

For directional drilling or operations involving sensitive electronic tools, we offer non-magnetic drill collars. These reduce interference with measurement-while-drilling (MWD) tools, improving accuracy.

Wear-Resistant Coatings

Extended tool life is critical for reducing operational costs. Our drill collars are available with wear-resistant coatings that enhance durability in abrasive drilling conditions.

Why Choose Our Drill Collars?

Customizable Solutions: Whether you need standard or specialized designs, we provide tailored solutions to meet your requirements.

Proven Reliability: Trusted by industry leaders, our drill collars deliver consistent results in the most demanding applications.

Technical Support: Our experienced engineers are available to assist with product selection, ensuring your drilling operations run smoothly.

Drill collars are more than just heavy pipes—they are the backbone of a successful drilling operation. By providing weight, stability, and precision, they ensure optimal performance in every wellbore.