Oil drilling is a complex and intricate process that requires a range of specialized equipment to ensure efficiency, safety, and environmental protection. Understanding the essential tools and machinery involved in oil drilling can help investors and stakeholders appreciate the technological advancements and investment potential in the oil and gas industry.

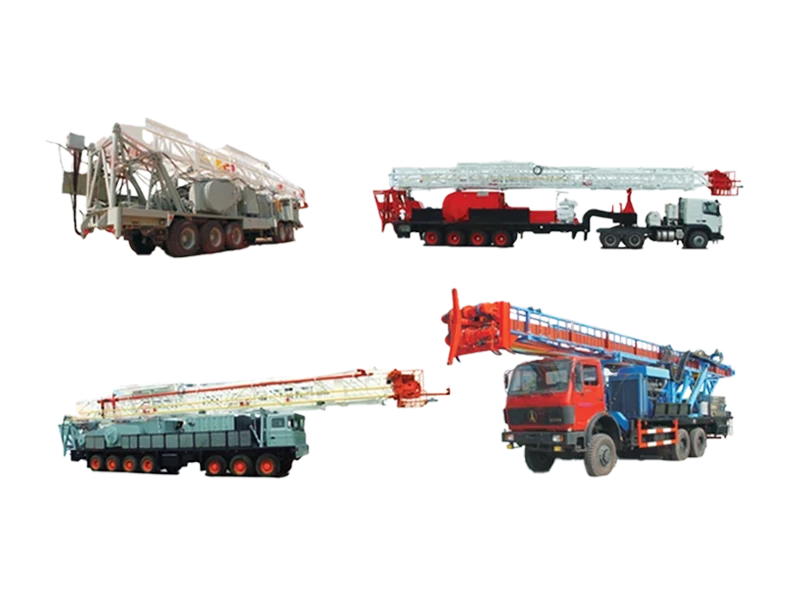

Drilling Rig

At the heart of any oil drilling operation is the drilling rig, which serves as the primary platform for the drilling process. Modern drilling rigs come in various types, including land rigs, offshore rigs, and floating rigs. Each type is designed for specific environments, and they are equipped with components like the drill string, rotary table, and top drive systems. The rig is engineered to provide stability and support during the drilling process, making it a crucial investment for any oil drilling project.

Drill Bits

Drill bits are essential for penetrating the earth’s surface to reach oil reserves. There are different types of drill bits, including roller cone bits and fixed-cutter bits, each designed for specific geological formations. Choosing the right drill bit can significantly impact drilling efficiency and costs. The durability and effectiveness of drill bits play a vital role in minimizing downtime and maximizing production, making them a critical consideration for any drilling operation.

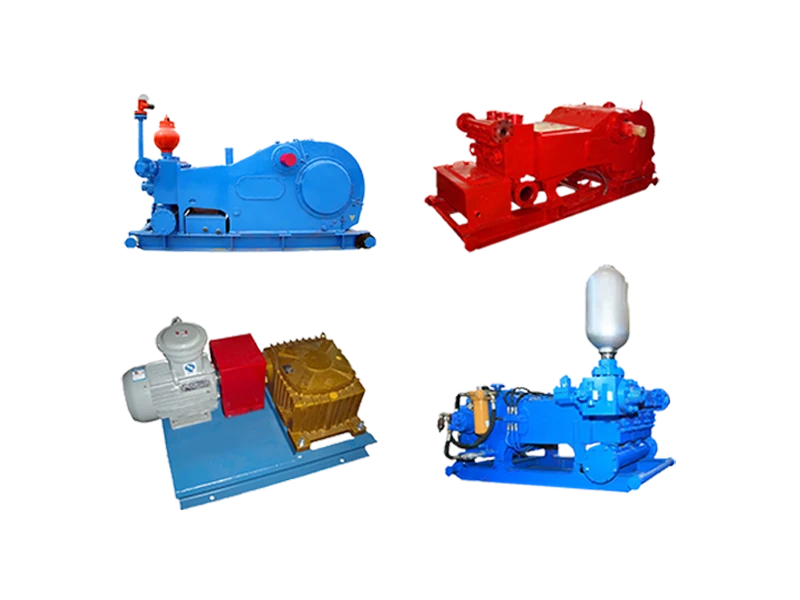

Mud Pumps and Drilling Fluids

Drilling fluids, or muds, are critical in the drilling process, helping to lubricate the drill bit, cool it, and stabilize the borehole. Mud pumps are used to circulate these fluids through the drilling system. The composition of drilling fluids can vary based on the type of formation and environmental conditions, so it’s vital to have the right mud system in place. Efficient mud management can improve drilling performance and reduce the risk of accidents, which is paramount for any operation.

Blowout Preventers (BOP)

Safety is a top priority in oil drilling, and blowout preventers are a crucial component in protecting workers and the environment. BOPs are installed at the wellhead and are designed to seal the well in case of unexpected pressure surges. These devices can prevent blowouts, which can lead to catastrophic accidents and significant financial losses. Investing in high-quality BOP systems can enhance the safety and reliability of drilling operations.

Casing and Cementing Equipment

Once the drilling reaches the desired depth, casing is installed to stabilize the wellbore and protect it from collapse. Cementing equipment is used to secure the casing in place, ensuring that the well is sealed and safe for production. Proper casing and cementing practices are crucial for preventing leaks and ensuring the long-term viability of the well.

Wellhead Equipment

The wellhead is the critical point where the drilling operation meets the surface. Wellhead equipment includes various valves and fittings that control the flow of oil and gas. This equipment is essential for managing production safely and efficiently. Investing in high-quality wellhead systems can enhance operational efficiency and protect the investment.

Surface Equipment

Beyond the drilling rig, other surface equipment plays a vital role in the oil drilling process. This includes storage tanks, separators, and processing units that manage the oil and gas extracted from the well. Effective surface operations can streamline production, enhance safety, and optimize resource management.

Investing in oil drilling requires a comprehensive understanding of the necessary equipment and technologies involved in the process. From the drilling rig to safety systems and surface operations, each component plays a crucial role in the efficiency and safety of oil extraction. For investors and stakeholders, recognizing the value of high-quality, state-of-the-art equipment is essential for ensuring successful drilling operations.

As the demand for oil continues, so does the need for innovative solutions and reliable equipment in the oil drilling industry. By staying informed and making strategic investments, stakeholders can position themselves for success in this ever-evolving market.