In the oil and gas industry, efficient, safe, and reliable tools are the backbone of successful operations. Among these tools, one stands out as essential for drilling: the drilling tong. Whether you’re familiar with the industry or new to the technical aspects of oil and gas exploration, understanding the purpose and advantages of a drilling tong can highlight its importance in the sector and underscore why it’s a key investment for any operation.

What Exactly Is a Drilling Tong?

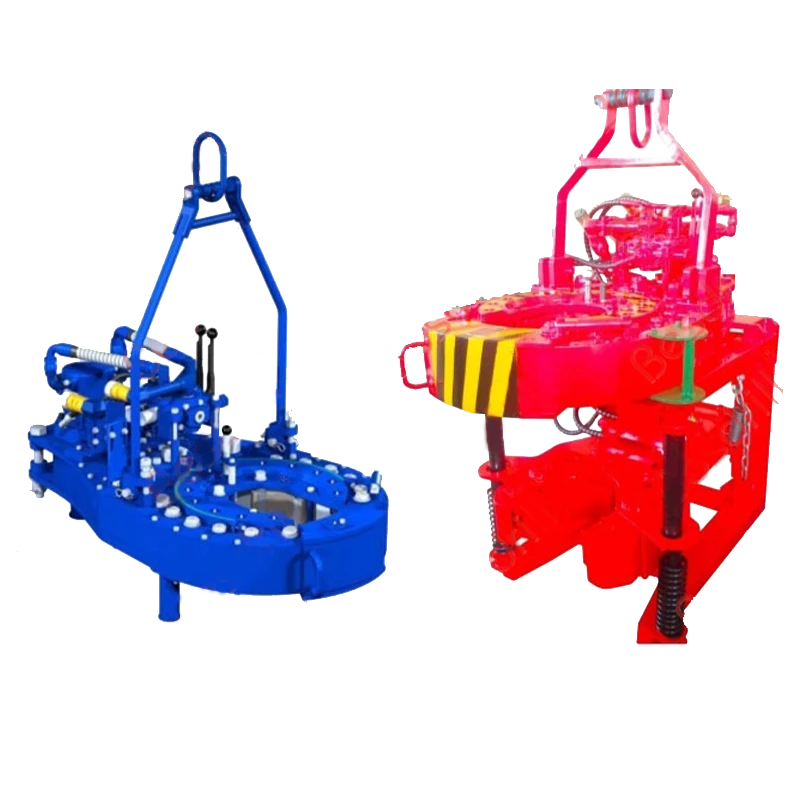

A drilling tong is a large mechanical tool used in oil drilling operations to grip and rotate the drill pipe, casing, or tubing as it’s lowered into or removed from the wellbore. Think of it as an industrial-sized wrench, specifically designed to handle the immense forces and torque required in oilfield drilling. Drilling tongs are operated in pairs—one set called the “lead tong” applies rotational force to tighten or loosen the pipe joints, while the “backup tong” holds the pipe steady to prevent unwanted movement.

Drilling tongs have evolved over the years, from manual devices requiring significant physical labor to fully automated systems. Modern drilling tongs are often hydraulically powered, ensuring faster operations, greater precision, and enhanced safety in high-pressure drilling environments.

Types of Drilling Tongs

Depending on the specific needs of a drilling project, various types of tongs are available:

Manual Tongs: These are the traditional types and are still used in some smaller or more remote operations. They require a team of workers to manually grip and rotate the pipe. While more labor-intensive, they can be a cost-effective solution in less complex drilling environments.

Power Tongs: These are hydraulically or electrically powered tongs that automate much of the manual work. They are capable of exerting greater torque and improving efficiency in larger drilling projects. Power tongs are often used in situations where speed and precision are crucial.

Casing Tongs: Specially designed to handle the larger-diameter casing pipe, these tongs ensure proper connection and sealing of the casing as it is run into the wellbore. A good seal is vital to prevent fluid leaks and ensure well integrity.

Key Benefits of Using Drilling Tongs

1.Improved Safety

Safety is a primary concern in the oil and gas industry.The manual handling of heavy and potentially unstable pipes can be hazardous, leading to injuries or accidents on site. Power tongs significantly reduce these risks by automating much of the handling process, reducing the need for workers to be physically involved in the tightening and loosening of pipe joints. Many modern tongs also come equipped with sensors and safety features that monitor and control the amount of force applied, minimizing the risk of over-torquing, which could damage the equipment or cause dangerous blowouts.

2.Enhanced Efficiency and Speed

In oil and gas drilling, time is money. Operations that take longer than expected can significantly increase project costs. Power tongs streamline the drilling process, making pipe handling faster and more efficient. Their ability to apply consistent torque with precision ensures that each pipe joint is tightened properly in a fraction of the time it would take with manual tongs. The use of drilling tongs is a key factor in reducing downtime and maintaining operational efficiency, which directly translates into cost savings.

3.Precision and Control

Drilling tongs, particularly the power variants, offer a level of precision that is difficult to achieve manually. With automated controls, operators can precisely adjust the torque applied to each pipe, ensuring that the pipe connections are uniform and secure.This precision is critical in deep and complex wells where even slight variations in pipe connection strength can lead to issues down the line, such as leaks or equipment failure.

4.Versatility

Drilling tongs are highly versatile tools. They can be used in a variety of drilling operations, whether dealing with standard drill pipes or specialized casing and tubing. This adaptability makes them an invaluable asset across different stages of drilling, from initial well setup to production and maintenance operations.

Investing in High-Quality Drilling Tongs

For companies in the oil and gas sector, investing in high-quality drilling tongs is not just about improving operational efficiency—it’s about enhancing the overall safety, precision, and productivity of their operations. The right equipment can significantly reduce the likelihood of accidents, minimize downtime, and ensure the long-term success of a well.

When selecting drilling tongs, it’s essential to consider factors such as the size and type of the well, the expected depth, and the material being drilled. Consulting with a supplier that offers a range of tongs suited to different applications ensures you get the tool best suited to your specific needs.

A drilling tong might seem like a simple tool at first glance, but in the world of oil and gas drilling, it plays a pivotal role. By improving safety, enhancing precision, and speeding up operations, drilling tongs are indispensable in modern drilling environments. For companies looking to optimize their operations, investing in the right type of drilling tong can make all the difference in achieving success in challenging drilling conditions.